Click here for Easter 1998 report

Click here for February 1999 report

Click here for March 1999 report

Click here for April 1999 report

Click here for May 1999 report

Click here for July (early) 1999 report

Autumn 1997

|

|

The tender and engine are separate

issues. The engine was taken into the Sheffield Park works during September for

the motion (internal Stephenson) to be dropped. The overall opinion was that

the condition of it was good. The tender meanwhile, as can be viewed from the

picture here has been receiving attention too. Volunteers (including some of

our Society members have cut the rivets that secure the tank from the chassis,

to enable it to be lifted. Most if not all of this will need to be renewed. The

frames of the tender have meanwhile been the subject of needle gun treatment

and painting.

|

During the early

part of 1998 the chassis was taken into the works at Sheffield Park for

inspection. The motion is in very good condition and was removed for cleaning

and safe storage. The lubrication pipework was also removed. The boiler has had

an inspect, and has been found to be in very good condition. it is without its

tubes, but the soundness of the boiler shell itself is reassuring. The boiler

stands just outside the works, and as you can see from the picture has been

receiving attention of late, to keep it in good condition. the cab (which is

that standing in front of the boiler, has also had the treatment, with a clean

up an paint job. As mentioned before, it is hoped to have the O1 running within

a "reasonable" time span, but realistically this is only going to be

achieved if it goes into the works for full time attention. Volunteers are

doing this and that to help though. The relatively good condition of the

engine, and the forthcoming 100 years anniversary of the SE&CR in 1999 are

likely to act as a suitable spur to get on with the job though, so I am

informed. Watch this space!

During the early

part of 1998 the chassis was taken into the works at Sheffield Park for

inspection. The motion is in very good condition and was removed for cleaning

and safe storage. The lubrication pipework was also removed. The boiler has had

an inspect, and has been found to be in very good condition. it is without its

tubes, but the soundness of the boiler shell itself is reassuring. The boiler

stands just outside the works, and as you can see from the picture has been

receiving attention of late, to keep it in good condition. the cab (which is

that standing in front of the boiler, has also had the treatment, with a clean

up an paint job. As mentioned before, it is hoped to have the O1 running within

a "reasonable" time span, but realistically this is only going to be

achieved if it goes into the works for full time attention. Volunteers are

doing this and that to help though. The relatively good condition of the

engine, and the forthcoming 100 years anniversary of the SE&CR in 1999 are

likely to act as a suitable spur to get on with the job though, so I am

informed. Watch this space!

February

1999

A lot has happened

since the last report that was published. The engine has acquired new impetus

to its restoration at the Bluebell with permanent workshop staff being assigned

to the job, to assist volunteers, with the target of restoration in time to

celebrate the South East and Chatham Railway; centenary a very realistic

possibility. Take a look at this shot of the frames which are now cleaned,

de-rusted and painted in SECR maroon.

A lot has happened

since the last report that was published. The engine has acquired new impetus

to its restoration at the Bluebell with permanent workshop staff being assigned

to the job, to assist volunteers, with the target of restoration in time to

celebrate the South East and Chatham Railway; centenary a very realistic

possibility. Take a look at this shot of the frames which are now cleaned,

de-rusted and painted in SECR maroon.

The frames are, as you can see stripped just about bare. Much is going on

with the relevant pieces. The piston and rods have been extracted from the

cylinders, both of which you can see here. The actual condition is not that bad

Not all the news is good I'm afraid. When the engine was bought from Ashford

works way back in 1963 the connecting rods were cut as a precursor to a trip to

the scrap yard. When Mr Esmond Lewis-Evans stepped in to save the engine,

they were welded up again. This was born out recently when the rods were ultra

sonically tested. One rod showed up very slight cracking at the end where the

"eye" of the rod is attached to the main shank. In this day and age,

that's enough to condemn it. Another will have to be cast and machined.

That isn't all, take a look at this picture. What you are

looking at is the journal of the leading drive axle. Its pitting is pretty bad.

The wheelsets have now been dispatched to Swindon for turning. This one though

may or may not skim down. The journal may have to be built up before it can be

turned to a sensible (i.e.: in tolerance) size.

The other wheelsets seem OK, and passed their ultra sonic tests. You can see

them here all in a line. The shot to the right shows the eccentrics on the

middle set that control the inside Stephenson valve arrangement. These are in

good condition give or take a bit of surface rust. As you can see they have

been needle gunned, tested and received their first coats of paint.

|

|

|

|

Other preparation work involves other removed items. The final two

pictures show the axle boxes which will get the white metal and machining work

to allow the frames to be rewheeled when the wheel sets return from Swindon,

and the cab which is in excellent shape requiring, when the time comes, just

fitting and the painters.

There is nothing to report as regards the boiler, which is stripped out, but

in super condition. This requires building up to a complete whole. No major

problems are anticipated in this area,... we'll see!

|

|

March 1999

Restoration carries on apace as the workshop team try to make

the target of the centennial celebrations of the South East and Chatham Railway

that will take place in July 1999. At the moment (March 1999) the engine is on

schedule, but it would only take one substantial snag to blow apart the engines

chances of making it to the show. Hopefully this wont happen of course. The

pictures show the current state of play. The wheels sets are back from Swindon

and are sporting their shiny tyres and journals. When the axles boxes have been

finished off the engine can be rewheeled. The boiler is getting a lot of

attention and is currently being retubed. The plan is to have the boiler in

place within a month. Good luck on that one lads!. The other big focus of

activity is the tender. As you can see the tender frames are on jacks whilst

the tender tank gets the treatment. Its on its side as you look at it. It is

having its "bad bits" cut out, so that fresh steel can be grafted in

as necessary. So far so good!

Restoration carries on apace as the workshop team try to make

the target of the centennial celebrations of the South East and Chatham Railway

that will take place in July 1999. At the moment (March 1999) the engine is on

schedule, but it would only take one substantial snag to blow apart the engines

chances of making it to the show. Hopefully this wont happen of course. The

pictures show the current state of play. The wheels sets are back from Swindon

and are sporting their shiny tyres and journals. When the axles boxes have been

finished off the engine can be rewheeled. The boiler is getting a lot of

attention and is currently being retubed. The plan is to have the boiler in

place within a month. Good luck on that one lads!. The other big focus of

activity is the tender. As you can see the tender frames are on jacks whilst

the tender tank gets the treatment. Its on its side as you look at it. It is

having its "bad bits" cut out, so that fresh steel can be grafted in

as necessary. So far so good!

|

|

April 1999

With the Centenary deadline getting ever closer, the workshop at Sheffield

Park has gone into overdrive to get the O1 ready in time. Some ground has been

covered in the 6 weeks or so since the last update. The following pictures tell

the story. In the workshop, the boiler has been retubed and fitted to the

frames

Of course prior to the fitting of the boiler, and its hydraulic testing came

the tube refitting. Funny to think that this was a serious major obstacle to a

preservation railway in earlier days, and now its almost routine.

The major work on the engine is matched by the efforts on the tender. The

previous report showed the tank being cut down. Now the plate is in the works,

being prepared and made ready to fit

Finally take a look at some of the small bits and pieces of jobs that are

vital to the overall appearance, and quality of job. The often appear to be

small jobs, but can in reality turn out to be as time consuming as the major

jobs. They also tend to demand a wide range of skills. The 2 examples shown

here certainly do!

Extra pictures - April 28th

To keep you bang up to date, and to show how time and effort is really being

put into the O1 to get it ready on time, these pictures show the current focus

of activity, namely the preparation of the boiler now its past its tests, and

the construction of the tender tank. The boiler is being lagged so the cladding

can be fitted, and then the painters let loose to get the complex Wainwright

SECR livery on. the tank meanwhile is being put together in the works, over the

nearside road. the MIG welder is the ideal tool for this task (that's the red

object in the middle of the tank)

May 1999

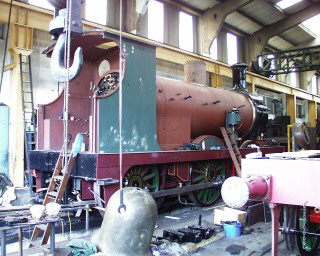

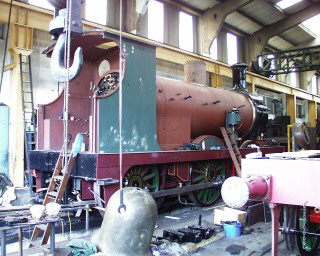

With

the deadline for completion fast approaching, No.65 is looking everyday, more

and more like an engine and tender. the tank for the tender is all but

complete, having been welded together, and the tender frames stand ready. the

engine mean while has be receiving various different types of attention. The

last rod to go on the motion is still missing as it has not quite yet been

retrieved from machining in Manchester. Fitting it however is not an onerous

task. The boiler however has been lagged and clad. No mean feat. this means

that the painters can get into action here having already done a splendid job

on the maroon frames and with the intricate wainwright style lining out on the

wheels. Take a look at the shots here and you will also see that the cab has

made it into position, giving the feel the the end is in sight. Much was done

to improve the condition of the cab, notably the renewal of its roof sheeting. With

the deadline for completion fast approaching, No.65 is looking everyday, more

and more like an engine and tender. the tank for the tender is all but

complete, having been welded together, and the tender frames stand ready. the

engine mean while has be receiving various different types of attention. The

last rod to go on the motion is still missing as it has not quite yet been

retrieved from machining in Manchester. Fitting it however is not an onerous

task. The boiler however has been lagged and clad. No mean feat. this means

that the painters can get into action here having already done a splendid job

on the maroon frames and with the intricate wainwright style lining out on the

wheels. Take a look at the shots here and you will also see that the cab has

made it into position, giving the feel the the end is in sight. Much was done

to improve the condition of the cab, notably the renewal of its roof sheeting.

|

|

|

The next steps will be to fit the tank of the tender in place,

and to fit the controls of engine onto the backhead. There's plenty of pipework

to go on although lubrication reservoirs are fitted to the sides of the

smokebox support, and positively gleam. naturally there's still plenty for the

painters to go at, in fact they are only now really starting to get into their

stride in terms of the finishing process.

|

July

1999

Its a race to the finishing line now, and progress is fast. A browse round

the gallery for the early July collection shows that the engine and tender look

like an engine and tender! Paint has been applied in numerous layers as the

distinctive SECR Wainwright scheme appears once again. It looks wonderful I can

tell you. The tender has been welded up and couple up to the engine, mainly to

see that it will still do that initially!!, but thereafter this will become a

common sight of course. The deadline is now under a month away, so take a look

at the pictures here, and make sure you get to the Bluebell for the SECR

centennial.

Return to 65 Profile

During the early

part of 1998 the chassis was taken into the works at Sheffield Park for

inspection. The motion is in very good condition and was removed for cleaning

and safe storage. The lubrication pipework was also removed. The boiler has had

an inspect, and has been found to be in very good condition. it is without its

tubes, but the soundness of the boiler shell itself is reassuring. The boiler

stands just outside the works, and as you can see from the picture has been

receiving attention of late, to keep it in good condition. the cab (which is

that standing in front of the boiler, has also had the treatment, with a clean

up an paint job. As mentioned before, it is hoped to have the O1 running within

a "reasonable" time span, but realistically this is only going to be

achieved if it goes into the works for full time attention. Volunteers are

doing this and that to help though. The relatively good condition of the

engine, and the forthcoming 100 years anniversary of the SE&CR in 1999 are

likely to act as a suitable spur to get on with the job though, so I am

informed. Watch this space!

During the early

part of 1998 the chassis was taken into the works at Sheffield Park for

inspection. The motion is in very good condition and was removed for cleaning

and safe storage. The lubrication pipework was also removed. The boiler has had

an inspect, and has been found to be in very good condition. it is without its

tubes, but the soundness of the boiler shell itself is reassuring. The boiler

stands just outside the works, and as you can see from the picture has been

receiving attention of late, to keep it in good condition. the cab (which is

that standing in front of the boiler, has also had the treatment, with a clean

up an paint job. As mentioned before, it is hoped to have the O1 running within

a "reasonable" time span, but realistically this is only going to be

achieved if it goes into the works for full time attention. Volunteers are

doing this and that to help though. The relatively good condition of the

engine, and the forthcoming 100 years anniversary of the SE&CR in 1999 are

likely to act as a suitable spur to get on with the job though, so I am

informed. Watch this space! A lot has happened

since the last report that was published. The engine has acquired new impetus

to its restoration at the Bluebell with permanent workshop staff being assigned

to the job, to assist volunteers, with the target of restoration in time to

celebrate the South East and Chatham Railway; centenary a very realistic

possibility. Take a look at this shot of the frames which are now cleaned,

de-rusted and painted in SECR maroon.

A lot has happened

since the last report that was published. The engine has acquired new impetus

to its restoration at the Bluebell with permanent workshop staff being assigned

to the job, to assist volunteers, with the target of restoration in time to

celebrate the South East and Chatham Railway; centenary a very realistic

possibility. Take a look at this shot of the frames which are now cleaned,

de-rusted and painted in SECR maroon.

Restoration carries on apace as the workshop team try to make

the target of the centennial celebrations of the South East and Chatham Railway

that will take place in July 1999. At the moment (March 1999) the engine is on

schedule, but it would only take one substantial snag to blow apart the engines

chances of making it to the show. Hopefully this wont happen of course. The

pictures show the current state of play. The wheels sets are back from Swindon

and are sporting their shiny tyres and journals. When the axles boxes have been

finished off the engine can be rewheeled. The boiler is getting a lot of

attention and is currently being retubed. The plan is to have the boiler in

place within a month. Good luck on that one lads!. The other big focus of

activity is the tender. As you can see the tender frames are on jacks whilst

the tender tank gets the treatment. Its on its side as you look at it. It is

having its "bad bits" cut out, so that fresh steel can be grafted in

as necessary. So far so good!

Restoration carries on apace as the workshop team try to make

the target of the centennial celebrations of the South East and Chatham Railway

that will take place in July 1999. At the moment (March 1999) the engine is on

schedule, but it would only take one substantial snag to blow apart the engines

chances of making it to the show. Hopefully this wont happen of course. The

pictures show the current state of play. The wheels sets are back from Swindon

and are sporting their shiny tyres and journals. When the axles boxes have been

finished off the engine can be rewheeled. The boiler is getting a lot of

attention and is currently being retubed. The plan is to have the boiler in

place within a month. Good luck on that one lads!. The other big focus of

activity is the tender. As you can see the tender frames are on jacks whilst

the tender tank gets the treatment. Its on its side as you look at it. It is

having its "bad bits" cut out, so that fresh steel can be grafted in

as necessary. So far so good!

With

the deadline for completion fast approaching, No.65 is looking everyday, more

and more like an engine and tender. the tank for the tender is all but

complete, having been welded together, and the tender frames stand ready. the

engine mean while has be receiving various different types of attention. The

last rod to go on the motion is still missing as it has not quite yet been

retrieved from machining in Manchester. Fitting it however is not an onerous

task. The boiler however has been lagged and clad. No mean feat. this means

that the painters can get into action here having already done a splendid job

on the maroon frames and with the intricate wainwright style lining out on the

wheels. Take a look at the shots here and you will also see that the cab has

made it into position, giving the feel the the end is in sight. Much was done

to improve the condition of the cab, notably the renewal of its roof sheeting.

With

the deadline for completion fast approaching, No.65 is looking everyday, more

and more like an engine and tender. the tank for the tender is all but

complete, having been welded together, and the tender frames stand ready. the

engine mean while has be receiving various different types of attention. The

last rod to go on the motion is still missing as it has not quite yet been

retrieved from machining in Manchester. Fitting it however is not an onerous

task. The boiler however has been lagged and clad. No mean feat. this means

that the painters can get into action here having already done a splendid job

on the maroon frames and with the intricate wainwright style lining out on the

wheels. Take a look at the shots here and you will also see that the cab has

made it into position, giving the feel the the end is in sight. Much was done

to improve the condition of the cab, notably the renewal of its roof sheeting.