![[View of Birch Grove ona train in 1970]](../../../pics/bn32_2_78_s.jpg) Birch Grove was bought by the Bluebell Railway in the Autumn of 1962 as a working

engine,

the largest the railway posessed at the time,

but also the one in poorest condition.

It worked until late summer of 1971.

(Click image for full size.)

Birch Grove was bought by the Bluebell Railway in the Autumn of 1962 as a working

engine,

the largest the railway posessed at the time,

but also the one in poorest condition.

It worked until late summer of 1971.

(Click image for full size.)

The engine it was taken out of service because of the poor condition of the boiler

and the mechanical parts.

At that time there was no prospect of repairing it,

because the railway had neither the money nor the facilities to attempt the work

which was required.

In the late seventies the boiler tubes,

which were only three years old,

were removed and shortened for use in Baxter's boiler,

for which we had no money to buy new tubes.

Repair work started in 1983.

On dismantling it was found to be in poorer condition than had been expected,

and after about two years work was shelved whilst another locomotive was

repaired.

The reason for this was that firstly Birch Grove could not have been repaired

within the timescale required to allow for other locomotives finishing their

boiler certificate periods,

and secondly when completed the poor condition of its cylinders and frames would

not permit it to work the kind of trains then being envisaged for the

coming extension of the line to Kingscote.

Earlier repair session

In this stage of the repair job the following items were done:

- Boiler partly dismantled:

- Inner firebox removed and seams re-rivetted

- Lower two-thirds of firebox side wrapper plates cut out

- Lower one-third of throatplate and backplate cut out

- New firebox outer wrapper plates obtained

- Corroded frames build up by arc welding

- Axleboxes rebuilt by fabrication

- Motion re-bushed and metalled

- Cylinders live-steam manifold patched

- New smokebox saddle and blastpipe fabricated

- Bunker platework replaced and strengthened

- Snap-head rivets on bufferbeams replaced with original-style flush rivets

The engine frame was then reassembled on its wheels.

![[View of boiler with firebox dismantled]](../473/bn33_2_99_s.jpg)

|

The boiler lying upside-down on the boiler trolley.

In this view you can see that the inner firebox has been removed,

and the outer wrapper plates cut down for new plates to be fitted.

|

As explained above,

Birch Grove was then put aside for a time.

During the following years only some occasional jobs were done on the boiler.

In 1994 the opportunity arose from the late Bernard Wright's legacy to employ

contract boilersmiths,

and they were directed to proceed with Birch Grove's repair.

The Villa Team took on much of the remaining tasks,

and some of the boiler work.

Later repair session

The boiler

Repairs to the boiler continued.

The copper inner firebox and new front tubeplate have been fitted,

it has been re-tubed,

and a new smokebox and ashpan made.

![[View of boiler]](../473/981_006_qs.jpg)

|

The boiler showing jobs in progress.

Read the story of the boiler repair

here.

|

Frames wheels and cylinders

As was noted above,

extensive work had been done some years ago on these parts.

The frames of the E4 class were prone to cracks and corrosion,

and no 473 required a great deal of arc-welding to repair this.

The cylinder block has suffered corrosion on top from the acid water formed in

the smokebox by condensation of water in the ash,

in the same way as has happened to Fenchurch.

In Birch Grove's case the corrosion has affected the live steam manifold,

which has been repaired with a patch screwed over the hole,

and which is now covered by the concrete smokebox floor.

A further remaining feature is that all the axle journals have worn down below

the normal size for scrapping,

although this is not a great concern at the low speeds at which the engine

will be running.

Click

here for details and pictures.

In view of these faults it is planned to restrict Birch Grove to loads of

about 140 tons,

and whilst it is expected to perform good work during its ten-year boiler

certificate,

it is quite likely that at some future repair it will require new frames and

cylinders.

Mechanical Parts

A few of the motion parts need re-metalling following more than a decade of standing

in the shed and being shunted around the yard.

The big ends were taken down for checking and found the be good.

The axleboxes were also checked and found OK.

The eccentric straps were remetalled and the motionwork reassembled.

Setting the valves took some time,

initially using an electric motor to turn the driving wheels with the

coupling rods removed.

On the engine's first test run the valve events were completely wrong,

but after a further setting exercise they are now as close to perfection as

is likely to be obtained on a slide-vslve engine.

Fittings

The Westinghouse air brake system has been completely overhauled.

All the old brake pipes were in poor condition and have been replaced,

with a modern-style second pipe installed.

|

The brake cylinder had been repaired some years ago when it was borrowed for

Fenchurch,

whose cylinder had cracked.

The triple valve needed only a good cleaning.

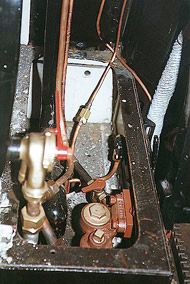

This picture shows the triple valve in the foregound and the brake cylinder,

mounted on the underside of the cast air reservoir which forms the cab

floor.

The large bar in the foregorund is the brake shaft,

and the frame in the background with a spring visible inside is the radial

axle.

|

![[View of triple valve and brake cylinder]](../473/97b_009_hs.jpg)

|

|

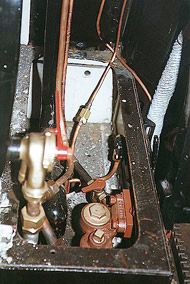

A view showing some of the complexity of the air braking system.

This is the box on the driver's side of the cab,

which is now covered with a wooden lid with only the driver's brake valve

readily visible.

|

In the above picture the brass-coloured object with the red handle rather out of focus in the

foreground is the driver's brake valve.

The brown object with bronze caps to its right is the feed valve which

regulates the air pressure to the driver's valve at 72psi.

The small handle just further away from this is the brake valve isolating cock,

used when two air-braked engines are double headed to ensure the second

engine does not attempt to release the brake.

The black object just visible on the right is the brake cylinder release cock,

used to release the air from the cylinder when the system is shut down.

The small pipe with an in-line connector goes to the train-pipe pressure gauge.

The large vertical black pipe on the left is the vacuum brake train pipe;

the larger of the two copper pipes running up it is to the "Jackson Valve"

which applies the air brake when the vacuum brake is applied

(the other is the vacuum ejector drain pipe).

The other small pipe in the background is from the auxilliary reservoir to a

new pressure gauge on the cab front,

which helps to verify that the system is working properly.

The white-insulated pipe is the steam supply to the injector.

|

The air pump had been looked at some years ago by MOD apprentices,

and was in store.

When Fenchurch's repair started it was expected that it would be a quicker job than

Birch Grove;

as its air pump was so worn out as to be almost unusable this was looked at early

on,

resulting in a complete rebuild by Fred Bailey into a virtually new pump.

As Birch Grove was to be finished first,

this pump was installed on it,

and Fenchurch will have Birch Grove's old pump

(the pumps are identical).

The picture shows the repaired air pump installed on the cab side.

Click

here for more details and pictures.

|

|

All the train heating pipework has been replaced.

Many of the lubrication pipes have also been replaced,

with some of the horn-guides having their lubrication changed from oil to

grease.

![[View of boiler back]](../473/985_016_ts.jpg)

|

The boiler backplate with all fittings in place.

|

Upper structural parts

![[View of new platework inside bunker]](../473/97a_010_hs.jpg)

|

The sides and back of the bunker were severely corroded,

and have been strengthened by new platework welded in between the various

support struts.

|

|

The left tank has had several new plates rivetted and welded into it to replace wasted

parts,

though the right tank is almost unaffected.

Both also need attention to various bits bolted onto them,

and both need new cladding plates made.

The picture shows a new section of plate fitted at the rear of the left tank;

the splayed-out head is not duff rivetting but actually a countersunk screw.

The large flanged hole is for the balance pipe to the rear tank.

|

![[View of new platework in tank]](../473/978_012_hs.jpg)

|

Painting

![[View of engine]](../473/985_007_ts.jpg)

|

The painting nearing completion bar a few details and the lettering:

|

![[View of engine]](../473/985_006_ts.jpg)

|

Go to the Villa Team Home Page, or the main web page for No. 473.

![[View of Birch Grove ona train in 1970]](../../../pics/bn32_2_78_s.jpg)

![[View of boiler with firebox dismantled]](../473/bn33_2_99_s.jpg)

![[View of boiler]](../473/981_006_qs.jpg)

![[View of triple valve and brake cylinder]](../473/97b_009_hs.jpg)

![[View of boiler back]](../473/985_016_ts.jpg)

![[View of new platework inside bunker]](../473/97a_010_hs.jpg)

![[View of new platework in tank]](../473/978_012_hs.jpg)

![[View of engine]](../473/985_007_ts.jpg)

![[View of engine]](../473/985_006_ts.jpg)