|

|

|

|

Locomotives - Operational Locos - Locos under overhaul - Locos on static display - Locos formerly based on the Bluebell Loco Roster - Loco Stock List - Loco Works News - Join the Loco Dept

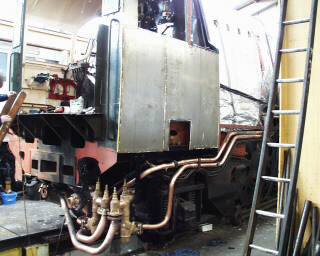

Initial work on the repair of Blackmore Vale concentrated on the boiler, which is now certificated. Work is now progressing on the engine sheeting and fittings, and on the tender. At a later stage the wheels will be dropped to check the axleboxes etc, but as it has run little mileage since its last major repair in the 1960s no great work is expected in this area. These pictures were taken on 28 February 1999.  A view of the left side of the engine, showing the boiler lagged and pipework being fitted.

A view of the left side of the engine, showing the boiler lagged and pipework being fitted.

A view of the right side of the engine.

The boiler feed pipes have been replaced with new piping from the unions just in front of the

firebox up to the clacks.

(The copper looks dull because they have been annealed by heating to red heat.)

A view of the right side of the engine.

The boiler feed pipes have been replaced with new piping from the unions just in front of the

firebox up to the clacks.

(The copper looks dull because they have been annealed by heating to red heat.)

A view of the cab showing boiler fittings in place.

The roof sheeting has been replaced with new.

A view of the cab showing boiler fittings in place.

The roof sheeting has been replaced with new.

New steel sheeting in place on the cab side,

and the injectors and pipework reinstalled..

All of the sheeting will be replaced so that the whole engine will look like new.

New steel sheeting in place on the cab side,

and the injectors and pipework reinstalled..

All of the sheeting will be replaced so that the whole engine will look like new.

Repairs have been made to the tender side sheeting.

Repairs have been made to the tender side sheeting.

The steam reverser,

previously one of its most unreliable components,

has been thoroughly overhauled.

Here Mike Carroll prepares it for refitting on the engine where few people will be able to see the

workmanship which has gone into it.

The steam reverser,

previously one of its most unreliable components,

has been thoroughly overhauled.

Here Mike Carroll prepares it for refitting on the engine where few people will be able to see the

workmanship which has gone into it.

The firebox stays have been tested using an ultrasonic instrument which detects breaks by measuring

their length.

Here Andrew Wilkens is testing some in the combustion chamber.

For many years it has always been the practice to test stays by tapping them

with a hammer and listening to the resulting tone. What we are using is a

modern development of that same technique by injecting a sound wave down the

stay and displaying the resultant echos on an oscilloscope in the same way

that sonar works. The equipment used is an "Ultrasonic Flaw Detector",

a comercially available instrument that is universally used to test welds

and platework for defects and is used throughout industry. The one that we

are using can be calibrated to test any length between 5mm and 1m. The

sound wave is reflected by a surface which can be the other end of the stay

or it could be a fracture.

The firebox stays have been tested using an ultrasonic instrument which detects breaks by measuring

their length.

Here Andrew Wilkens is testing some in the combustion chamber.

For many years it has always been the practice to test stays by tapping them

with a hammer and listening to the resulting tone. What we are using is a

modern development of that same technique by injecting a sound wave down the

stay and displaying the resultant echos on an oscilloscope in the same way

that sonar works. The equipment used is an "Ultrasonic Flaw Detector",

a comercially available instrument that is universally used to test welds

and platework for defects and is used throughout industry. The one that we

are using can be calibrated to test any length between 5mm and 1m. The

sound wave is reflected by a surface which can be the other end of the stay

or it could be a fracture.

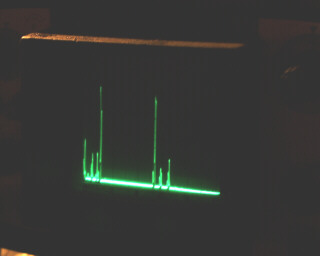

An example of the display obtained from a sound stay.

The X axis of the screen is a time base and the

instrument is effectively measuring the time taken for the ultrasonic signal

to travel from the probe to the reflecting surface and back again. The speed

of sound is different for different materials and hence if you tested an 8

inch copper stay and an 8 inch steel stay you would get a trace at a

different position on the screen. In order to test a row of stays we

calibrate the machine so that the trace for a complete stay is set at 75%

along the screen. We then lightly clean each stay head with a wire brush and

put a small dab of grease on the head to act as a couplant. Each stay is

then tested and the traces should all appear at the 75% point on the screen.

If a stay has a trace at say 50% of the screen this will show that the stay

has a reflective surface part way along its length which will indicate that

it is either fractured or cracked. There is still some further work to

perfect the technique and we will be looking to try this application on

crown stays but it has already detected broken stays in boilers which have

then been confirmed visually.

An example of the display obtained from a sound stay.

The X axis of the screen is a time base and the

instrument is effectively measuring the time taken for the ultrasonic signal

to travel from the probe to the reflecting surface and back again. The speed

of sound is different for different materials and hence if you tested an 8

inch copper stay and an 8 inch steel stay you would get a trace at a

different position on the screen. In order to test a row of stays we

calibrate the machine so that the trace for a complete stay is set at 75%

along the screen. We then lightly clean each stay head with a wire brush and

put a small dab of grease on the head to act as a couplant. Each stay is

then tested and the traces should all appear at the 75% point on the screen.

If a stay has a trace at say 50% of the screen this will show that the stay

has a reflective surface part way along its length which will indicate that

it is either fractured or cracked. There is still some further work to

perfect the technique and we will be looking to try this application on

crown stays but it has already detected broken stays in boilers which have

then been confirmed visually.

Return to BRPS Home Page, to the Timetable or to Special Events

Current Loco Works News - Recent Archive News - 1997-2003 Archive News - Villa Team Pictures

Visitor Info. - Museum - Trust - Catering - Contacts - What's New - Projects - Locos - Carriages & Wagons - Signals - History - Other - Links - Search - FAQ Why not become a BRPS Member? - Get more involved as a Volunteer © Copyright BRPS. Privacy Policy |