The injector is a simple,

if unlikely sounding device that was invented by the the Frenchman M. Giffard

in the 1850s.

It uses a jet of steam,

from the boiler to force fresh water back into the boiler,

heating it up in the process.

It has virtually no moving parts and is thermally very efficient.

It has been widely used on steam locomotives since its invention.

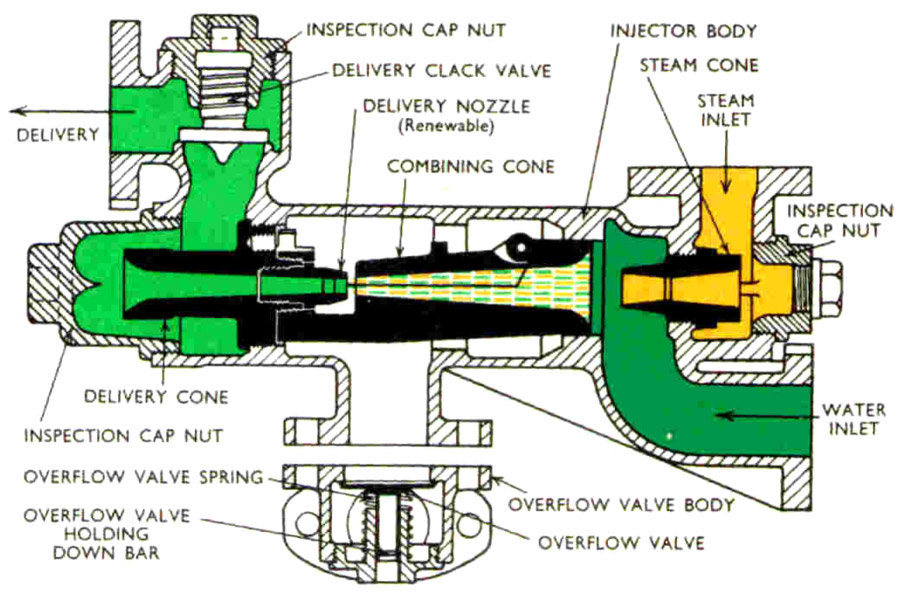

The sectioned drawing,

and photographs show a new GWR pattern injector that will be fitted to

'Dukedog' 3217.

These injectors are very reliable,

and after nationalisation of the railways,

the design was adopted in three sizes for the new BR Standard locomotives.

Steam from the boiler,

and water from the tank or tender,

pass through a stop valves (taps) controlled by the fireman.

When he wishes to increase the level of water in the boiler he turns on the

water and steam valves.

Initially water passes into the injector by gravity,

where it lifts the hinged combining cone flap,

pushes down the overflow valve and runs out of the overflow pipe onto the

ground.

When the steam valve is opened,

a jet of steam escapes from the steam cone.

This jet has a high velocity,

which it imparts to the surrounding water.

At the same time the cold water starts to condense the steam jet.

During condensation the volume of the steam is vastly reduced,

so a partial vacuum is formed which

(a) draws more water from the tank,

(b) closes the overflow valve,

and (c) shuts the hinged combining cone flap.

The mixture of condensing steam and cold water continues to gain speed as it

travels through the combining cone.

It emerges from the small end of the combining cone as a jet of hot water.

It then travels across the gap and into the divergent delivery cone.

Here the speed of the jet is reduced,

but its pressure is increased sufficiently to lift the delivery clack

(non-return valve)

and flow into the boiler.

The 10X injector for 3217 will deliver about 40 gallons of water per minute

into the boiler.