Carriage & Wagon Dept -

Stock Lists: Carriages, Vans, Wagons & Multiple Units -

C&W News

SR Coach Group - Goods Division -

Operation Undercover -

Technical -

Join us

Notes on the Covering of

Wooden Carriage and Van Roofs

Traditionally a timber Railway Carriage roof was covered by Canvas. A "Bluebell News" article (Winter 1981) covered our experiences of this technique, and my thanks are due to Mark Smith for preparing this section of the page.

The LNER Coach Association have, on their web site, a draft roofing specification (Download PDF), to which the intending carriage re-roofer is recommended. This covers the application of canvas, using a modern bedding material. On the Bluebell we still adhere to the old bedding compound of chalk in linseed oil.

The LMS Carriage Association have a video on YouTube showing re-canvassing.

In addition notes are provided here about the use (now considered problematic) of a modern synthetic material, as used on curtain-sided lorry trailers, and also for aluminium roofing, as applied to a couple of our more up-market vehicles. Further notes are included about "Sagging roofs", and repairs to timber carriage/wagon roofs.

Roofing felt has the disadvantages that it involves putting nails into the roof, and, with time it becomes brittle and does not flex as the coach body moves, so cracking, letting in water. We have in the past used it for static vehicles, as a temporary measure, but would probably now use the synthetic material in these circumstances.

Canvas:

(Article from the 21st Anniversary special edition of "Bluebell News", Vol.23 No.4 (Winter 1981) by Roger Williams,

prepared for this web page by Mark Smith)

"TWENTY ONE YEARS OF CARRIAGE ROOFING"

The three "BR Standards" and the two LMS sleepers apart, all Bluebell

carriages have wooden roofs, as have all

but one of the railway's vans and covered wagons. In this respect we are

probably unique in the railway

preservation field, where with few exceptions all steel BR Standard Coaching

Stock provides the typical train.

On the Severn Valley Railway rakes of Great Western and LMS coaches

similarly have galvanised steel roofs.

A sound and watertight roof is the key to effective carriage preservation

and the railway's first two decades

witnessed a continuous battle with the elements.

The early 1960s were years of unprecedented modernisation on the

nationalised system. Ageing carriages were

being discarded at a prodigious rate and the early Bluebell acquisitions

were with few exceptions nearing the

end of their economic lives. Only those masterpieces of carriage

constructions 1098 and 971 were to remain

serviceable throughout the 1970s. Few had received general overhauls since

the late 1940s. Small wonder

therefore that the leaking carriage roof became a major problem in the

formative years of the railway. The

Chesham Set, which formed the backbone of the service fleet from 1961 to

1965 was particularly bad in this

respect and its complete demise the following year was a direct result of

the failure of the roof-covering over

many years leading to rotten partitions, roof boards and a decaying

moquette.

No easy solution to the problem was forthcoming for the railway was devoid

of covered accommodation and

wholesale re-roofing could not be contemplated. The early working membership

was bereft of specific

experience of railway carriages and the first "re-roofings" were undertaken

with a domestic type of roofing felt,

1050 and the Observation Car being two of the vehicles so treated. This

covering with its many joints proved

brittle and unsatisfactory, when applied to a wooden bodied railway carriage

which tends to move or "work" on

its underframe, particularly in advancing age.

As the decade wore on the problem became more acute as more and more

vehicles succumbed, 1098's roof

covering was such that the vehicle could only be used at times of extreme

pressure and 6575 developed a

tendency to leak in the vicinity of the first class compartments.

Worse the prestigious LBSC Directors' Saloon was leaking with well nigh

irreparable damage to the ornate

lincrusta ceiling. With no prospect of covered accommodation for carriages

the problem was rapidly assuming

crisis proportions, when in June 1968 the Carriage and Wagon Superintendent

of the day, Norman Gillett, an

architect by profession, approached the Turnerised Roofing Company, a firm

which patented a process not

unknown to the building industries. Briefly it involved the bedding of a

cotton cloth in a hot bituminous

solution, the whole roof subsequently receiving several coatings of the same

solution.

Although never previously applied to railway carriages, the process had

several attractions, not least the

minimal preparatory work that was required and the three year guarantee

afforded by the contractor. Roof

furniture could remain in position and scarce volunteer labour might be

redirected to other aspects of carriage

restoration.

The first victim of the new process was the Directors' Saloon, which

received the full treatment at a price of £78.

6575, the Observation Car and several other vehicles followed with an

impressive measure of success. For a time

it seemed that the battle might have been won. It gradually became clear,

however, that a permanent solution to

the problem was as elusive as ever. By 1972 leaks had reappeared,

particularly around cant rails, where water

would continue to get behind the cloth, causing it to lift. Further

disintegration of the original covering

occurred, if anything hastened by a reaction with the bitumen inherent in

the Turnerising process.

1973 was a crucial year. In the course of its long restoration Bulleid Open

Third No 1482 had its entire roof

completely stripped of its former covering and was submitted to the

Turnerising process with indifferent results.

The covering proved too thin and brittle to cope adequately with the

expansion and contraction between the

roof boards. In service it has proved a constant source of anxiety to those

concerned with the day to day

maintenance of the carriages. Armed with the knowledge that the Severn

Valley had recently recovered the roof

of one of the two Southern "ex-Longmoor saloons", it was decided to

experiment with this process, which

although more expensive had served the railways well over many years.

As in so many other fields in the early "seventies" it was the Bulleid

Society who took the lead, when it agreed

to fund the recanvassing of Coach 5768. A specially treated, close-woven

canvas was ordered, together with

the necessary bedding down compound, eight "nine kilo" cans being necessary

for the one roof.

At that time the department did not posses sufficiently tall trestles or

indeed the working space to enable the

job to be undertaken in the shed and the vehicle coupled between two other

coaches was taken into platforms 3

and 4 in the station for the work to be done.

In those days a whole weekend could pass before the canvas was properly

bedded down. Today with better

facilities and more experience it has been possible to recanvas two roofs in

a day. The "5768" operation took

place on the weekend of 22nd September 1974, although for various reasons it

was not to see regular service

until May of 1977.

In the meantime the complete failure of the roof covering on S.E.C.R. Coach

No 1098 led to that being

recanvassed in 1975, the vehicle having the distinction of carrying the

first "Bluebell Canvas Roof" in traffic.

The result was remarkable - a hitherto damp and musty vehicle has been

transferred into one which has

operated without a leak in the worst conditions. To this day, only biennial

repainting has been necessary.

With the canvas roof having proved its worth further vehicles received the

treatment, which is now standard for

all Horsted Keynes based carriages and vans. Over the years the following

carriages and several vans have

received new canvas roofs:

2515 (Bulleid Brake Third) in 1976

2356 (C&W Mess Coach Third) in 1977

4279 (Bulleid Brake Third) in 1978

971 (S.E.C.R. Third) in 1979

1503 (Observation Car) in 1980

6575 (Maunsell B.C.K.) and 4444 in 1981

The recanvassing of a roof is an operation which required commonsense and

application rather than any

particular skill, the most tedious part being the clearing and smoothing of

the roof boards, once the old material

is removed, an operation which takes up to 12 man-days. The actual

recanvassing involves at least 8 people and

care must be taken to ensure that the canvas is smoothly bedded down and any

air pockets eliminated.

Subsequently the roof must be painted, with at least 5 coats, and

reconditioned roof furniture, together with

new cant rails and rainstrips fitted. This latter operation is particularly

important as care must be taken to ensure

that any water will run off the roof rather than accumulating in depressions

in the centre of the strip or rail.

With 21 vehicles now benefiting from canvas roofs, it might well be thought

that this proven roof covering

would be standard throughout the railway. Surprisingly this is not the case.

Many of the "support" vehicles

purchased by the various locomotive groups at Sheffield Park sport a variety

of roof-coverings or none at all.

Surely they are entitled to the best as the locomotives in connection with

which they were acquired. Whether it

is a traffic vehicle or stores van, a canvas roof is "covered

accommodation".

Roger Williams

C&W Department.

You are recommended to The LNER Coach Association's draft roofing specification (Download PDF) and the LMSCA's Video for full details of how to canvas a carriage roof.

Suppliers:

Traditional coach roofing canvas: Mitco - Andrew Mitchell & Co. - web site

Bates Business Centre, The Old Brickworks, Church Rd, Harold Wood, Essex RM3 0JF

Tel: 01708 370800 (Fax: 01708 377190)

Bedding Compound (Chalk in Linseed Oil):

Roof canvas bonding: BR Spec 77 item 12, from:

T.R.Williamson, 36 Stonebridgegate, Ripon, N.Yorks HG4 1TP

Phone: 01765 607711 (Fax 01765 607908)

The modern alternative to canvas:

(notes by Richard Salmon, January 1999, updated 17 November 1999, 15 August 2000, Jan 2009)

On the Bluebell we have used both traditional canvas, and also modern automotive plastic material, in a fire-proof grade, as used in curtain-sided lorries and the like. This material has been used for many years by some other preservation bodies, and on departmental vehicles on the old BR. It was hoped that it would give a longer life than canvas, but has caused serious problems where hot cinders from the loco have melted holes in the material. It is easier to apply, but is more difficult to avoid wrinkles. In our limited experience it works better (appearance wise) on arc-roofed stock than semi-eliptical, although both Bulleid Brake 2515 and the VCT's Matchboard Brake have worked well, as has SR van 404. It is available in a variety of colours (grey and white are the most useful for railway use) and does not need painting. The material we have used on our Metropolitan coaches has a surface texture not that dissimilar from painted canvas. It does seem to attract dirt rather more than a painted roof, that on 2515 having become a much darker grey as a result.

Warning: We are no longer using this material on traffic vehicles following experience that hot cinders from locomotives have melted holes in the roof covering on several coaches. It is, however, a very useful material for static vehicles, such as stores vans, or coaches some way down the queue for restoration. Painting the material also appears to help prevent much of the problem caused by smaller cinders. Larger cinders tend to end up rolling down until they reach the rain-strip, where a hole in the roof covering is most unfortunate. Reinforcing this area with a strip of flash-banding has provided a temporary solution.

You can obtain complete vehicle lengths of both canvas and the synthetic material in a single run. The synthetic material is made up from (two) strips, welded together, wheras the canvas may be made from more strips than this, stitched together. One other user of this material had a slight problem on one vehicle, since there was a fault in the seam (they didn't discover it until it had been on the vehicle for a good many years) and were able to partially remove the material, repair a rotten roof-board and the fault in the material, and re-fix it. Try doing that with traditional canvas!

For any re-roofing, of course, you have to start by stripping all fittings and roof furniture, as well as whatever mouldings around the edge are used to cover the row of tacks which hold the canvas on. All sharp edges and broken-off pins/screws must be removed from the entire roof surface. If the cant-rail or roof-edge where the tacks go is rotten you may need to get into structural repairs before fixing down the canvas.

Any sharp edges where the boards have warped/cupped are best sanded/planed down. Unless the gaps are serious, in which case a little filler might sort out the problem, providing you're not going to spend too long walking on the roof, some small gaps are of little consequence. If there are holes where roof vents have been removed, and if you are not replacing the roof vents, it might be as well to tack a piece of aluminium or steel sheet over the hole before re-covering the roof, although if the vehicle is to re-enter passenger service, a proper timber repair should be effected.

Traditional canvas is more labour intensive, and really needs to be done under cover in the dry. The process takes several days, since you have to allow time for each coat of paint to dry. For the synthetic material, which does not require bedding down, it should be possible for two people to complete the operation in a weekend. The condition of the ground around the vehicle will affect how much time it all takes. We have a shed with concreted surfaces, which is something of an advantage!

With either material it's best to lay the material out on the roof (or somewhere else) for some time in advance so that the creases fall out.

The best method we found for fixing the synthetic material is as follows:

Lay it out along the roof. Fix the centre of one end with a number of tacks. One person now goes to the other end, stretching the material, maintaining a straight line down the coach (it was helpful to have a seam running dead centre). Rolling the spare material around a 2-ft long wooden bar helped this tensioning process. The second person, wearing soft shoes, goes down the centre of the roof, fixing tacks in along the centre line where they will be covered by the rim of torpedo vents (if they are so positioned!), until you reach the other end, where the center can be tacked in place. If you have no such roof funrnature, this is not a problem, and there is no need to do anything but fix the two ends. We then worked across each end and along each edge, putting tacks in every three inches, ensuring that the material was not creased. It may help to put a tack in about a foot ahead and then fill in in-between. Where the material is not held along the centre-line of the roof, it may be advisable to work down both sides simulataneously.

Where you have pipes and tanks coming up out of the roof, tacks will be required. I would cover the joint with an aluminium or hardwood moulding, suitably sealed with mastic, and so covering the tacks. Fittings such as rain-strips and torpedo ventilators are fixed down with screws, and should be sealed down with either mastic or, better, arborseal.

This technique worked for us, but it appears to be very much more difficult to avoid creases in the synthetic than in the traditional canvas. This is the reason I recommend the synthetic more for arc-roofed vehicles, since any creases are less visible than on the near vertical edge of a semi-eliptical coach roof. However, it appears that, with time, minor wrinkles in the synthetic material become less noticable, and we were well pleased visually with the result on both our Metropolitan coaches and the LBSCR Bogie First, until the cinder holes appeared! The SR Passenger Luggage Vans which have received this covering also look good. We are now intending to re-cover the roofs of the first two metropolitan coaches with traditional canvas, and the third carriage has already been done in this manner.

In 1997 we were using both methods - our two Bulleid Brakes' roofs were re-covered that year, one with each material, so we should be able to perform a long-term comparison. The roof canvases seem to start leaking after typically 15 years, and replacement rather than patching becomes necessary after 20 years. This period will tend to be shorter if the carriage body is in less than first-class structural condition, since the working of the wooden structure will tend to open up cracks in the paint covering the canvas.

Costs: The synthetic material (in a suitable fire-proof grade) costs a similar amount to traditional canvas (in the region of £4-500 for a 60-foot coach), but the latter ends up rather more in total due to the costs of the bedding compounds.

Manufacturer: We have obtained the synthetic material from:

Mudfords (Sheffield) Ltd

400, Petre St

Sheffield South Yorkshire S4 8LU

Tel: 0114 243 3033

Aluminium covered roofs:

(notes by Richard Salmon, January 1999)

The other roofing technique not previosuly discussed, is aluminium. This we have used on Pullman Fingall and the GNR Directors' Saloon. It is also used by the VSOE on their wooden-bodied Pullmans. Traditionally the ends of Pullmans were covered in shaped copper, with the central, straight, section of the roof canvassed. Doing the whole roof in relatively narrow aluminium strips off a roll is expensive, especially when it has to be shaped at the ends. However, it is not a ridiculous cost, and should be rather more durable than canvas. The joints are screwed, and bedded down with arborseal; ordinary mastic will tend to work out of the joints, giving rise to leaks.

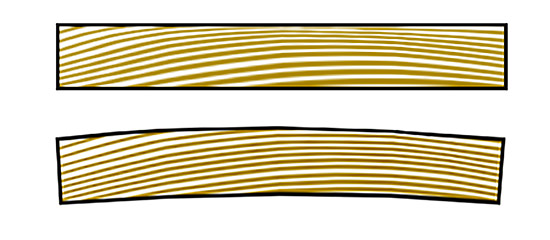

Sagging Roofs:

(notes by Richard Salmon, January 1999, updated Feb 2000, Jan 2009)

This is a frequent "feature" of old arc-roofed coaches. Even the eight-foot spans between partitions on our Brighton bogie first show signs of sagging. It doesn't necessarily mean that there's anything major wrong with the roof. Particularly in a vehicle which has had internal partitions removed, this may happen, and can usually be rectified by gently jacking up the inside with a suitably shaped support on acro-props, and then re-inserting a partition, or, if you wish to keep the interior open, some extra, deeper roofing sticks, as we have applied to the interior of the luggage area of Metropolitan coach 387. Note that as the roof is jacked up the sides must be free to come back in to their original width.

On one vintage carriage where the roof had sagged slightly between partitions and where the roof had to be removed in any case, it was decided to re-profile the oak roof-hoops by steaming them and clamping to a curved former. A wallpaper stripping steamer provides the steam, and the roof hoop is enclosed within a flexible drain-pipe or flue-tube liner etc. About 1 hour steaming was required for re-tensionning an existing curved member, but rather more would be required before bending new timber (allow at least an hour per inch of cross section). Laminating and glueing together thinner more flexible sections is another useful technique for making roof hoops.

Repair/replacement of timber roofs:

(notes by Richard Salmon, January 2022)

Timber roof hoops on carriages and vans are sometimes steamed and sometimes cut from solid timber - often those on 20th century carriages are the latter, especially when bolted to a metal hoop, when their purpose is simply to take the screws to hold down the T&G roof timbers (incidentally, we now always use stainless steel screws for this).

If steamed, Ash is the normal choice, but softwood is fine if cut from the solid, in sections, if the steel provides the strength.

To steam an Ash hoop we have used a wallpaper steamer feeding a length of plastic drainpipe, with ends sealed with tape. The pipe is tilted so that steam enters at the top and condensate drains from the bottom. It's normal to allow 1 hour steaming per inch of cross section.

The hot timber is then clamped to a former at a slightly tighter radius than that required of the finished hoop. It needs to be over length by maybe 8 inches each end, to enable the ends to adequately take the curve.

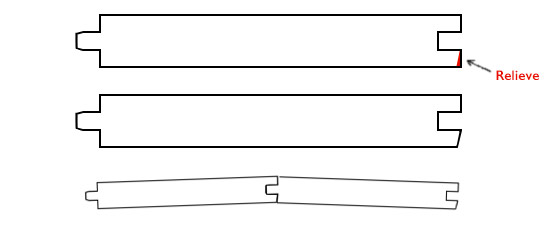

So far as the roof timbers themselves are concerned, 3/4-inch thick tongued and grooved joinery quality softwood timber is generally used these days (since quality pitch pine is unavailable). It needs to be well seasoned, since the timber will shrink significantly opening up gaps. It's useful to relieve the side of the board adjacent to the grove on the inside to help the boards sit in a gentle curve, as per diagram on the right.

So far as the roof timbers themselves are concerned, 3/4-inch thick tongued and grooved joinery quality softwood timber is generally used these days (since quality pitch pine is unavailable). It needs to be well seasoned, since the timber will shrink significantly opening up gaps. It's useful to relieve the side of the board adjacent to the grove on the inside to help the boards sit in a gentle curve, as per diagram on the right.

The boards are clamped up to each other, and then screwed down, starting in the centre and working down each side. Allow sufficient additional material to cover shrinkage, and don't trim the edges until finally fixed in place.

On an elliptical or 3-centred roof, rather than an arc roof, the sharper curves towards the edges are made from narrower boards, which may additionally need to be shaped to fit the curve, possibly with tongues/groves at an angle too. Loose tongues made from offcuts of hardwood can be useful as well.

Before canvassing it's important to plane/smooth off any sharp corners to avoid there being patches with thin covering of bedding compound. In addition, since boards can tend to cup as they dry out over time, it's helpful to place the boards such that the cupping follows the shape of the roof, rather than opposing it. The diagram right shows the end-grain and the cupping which can occur.

Before canvassing it's important to plane/smooth off any sharp corners to avoid there being patches with thin covering of bedding compound. In addition, since boards can tend to cup as they dry out over time, it's helpful to place the boards such that the cupping follows the shape of the roof, rather than opposing it. The diagram right shows the end-grain and the cupping which can occur.

Both Ash and softwood should be treated with wood preservative.

Return to BRPS Home Page,

to the Timetable or to Special

Events

Carriages & Wagons -

Intro -

Development -

Stock Lists: Carriages, Vans, Wagons & Multiple Units -

Carriage Fleet Review -

Join us

C&W Works News - SR Coach Group - Goods Division -

Operation Undercover -

Carriage Shop -

Technical Pages

Visitor Info. -

Museum -

Trust -

Catering -

Contacts -

What's New -

Projects -

Locos -

Carriages & Wagons -

Signals -

History -

Other -

Links -

Search -

FAQ

Why not become a BRPS Member? -

Get more involved as a Volunteer

Your ideal Film/TV location?

Copyright © 24 January 2022.

Copyright © 24 January 2022.

Last update 29 December 2019 by Richard Salmon.

© Copyright BRPS. Privacy Policy

|