Carriage & Wagon Dept -

Stock Lists: Carriages, Vans, Wagons & Multiple Units -

C&W News

SR Coach Group - Goods Division -

Operation Undercover -

Technical -

Join us

Goods Division: Home - Shop - Projects - Instagram - Flickr - Facebook - Donate

Carriage & Wagon Works News

Southern Railway 13 Ton 5-Plank

Open Merchandise Wagon No.12058

Initially acquired in 2005 as a stripped underframe from use at Eastleigh Works as a shunting adaptor wagon, it had been intended as a source of spare parts. However it was soon realised that this was an interesting wagon, to SR diagram 1375, and further investigation established it was a unque survivor of its sub-type.

In 2007 The Bulleid Society agreed to part-sponsor the materials

to restore SR 12058 as, being built in January 1946, it is a

‘Bulleid-era’ wagon. The remaining funding has been raised by the Bluebell Railway Goods Division, with match funding from The Bluebell Railway Trust.

Work proceeded over the following years towards

its restoration, despite several unavoidable issues causing work to be paused. In late February 2011 the underframe was rerailed and work could continued until it had to be set aside due to the lack of anywhere to work on it whilst the OP4 site was cleared and the new shed built.

At the start of 2019 work re-started, with the underframe largely taken back to bare metal and repainted, and a start made on assembling those parts already available. Having again been set aside during the COVID lockdowns, work has moved up a gear in the final two years leading to its completion in February 2023 (as seen in the photo below), where it just awaits the painting on of its tare weight on the further corner.

This wagon is a unique survivor of the batches built originally with thinner English hardwood planking due to the difficulty in obtaining the normal softwood following wartime supply constraints. Another interesting design variation is that the middle three of the five side and end planks were not conventionally bolted into place, but said to be held by "clips", but no drawings showing what form these took have yet been discovered.

Our new floor is made from Iroko which has very similar similarities to teak in that it is very water resistant, however considering the cost of the timber we have decided to treat the holes, ends of the timbers and floor packers with an epoxy resin. This will ensure a good long life in the timbers and prevent water rotting the wood. Since all but two of the side planks were unpainted originally, a cheaper imported hardwood was not going to look right, so Oak has been used for the sides, ends and doors. End-grain has been similarly treated with resin, and a wax/oil used on the surfaces. Just one plank each side is painted, that carrying the lettering.

December 2022 to February 2023

The West side of the wagon was essentially completed in the Autumn, however, whilst work on this wagon could proceed outside, the work on Engineers Wagon 62002, which was also nearing completion, really needed to take priority when a space in the shed became available. Laurie Anderson's photo shows the wagon looking more complete than it actually was, in the snow on 11 December.

Work however continued on 12058 in terms of preparing the planks for the East side, and outside when the weather was enticing enough these were erected and this work was complete by mid-January, as seen in the first photo below. The last major element to be completed was the tops of the doors. A particular challenge was drilling the stainless steel door capping, angled on one side, and fitting low-profile bolts where there had originally been rivets.

With 62002 outshopped and Stroudley Brake No. 949 entering the paint shop for a week, there were briefly two spaces in the works, and over half term a concerted effort was made to complete 12058, and the opportunity also taken to smarten up SR 8-plank No. 37786. Below we see the bolts on 12058 cut down, primed and undercoated. The door capping has also been fitted, and the bolts are seen here also being trimmed by Laurie.

Very little remains to do now except fixing the capping strips on the fixed planks, and the final bits of painting and lettering.

September 2022

With the hinges complete, following grit-blasting and priming, the planking of the doors has become the priority, since this was a pre-requisite for completing the fixed side planks.

The ends of the boards (both door and bodyside), are cut to 17 degrees.

The end result was a rapid (dry) assembly of the south-west corner of the wagon. Once end-grains are sealed, final assembly using Arboseal between metal and timber can follow, depending on the weather, through the autumn.

August 2022

With the wagon now sitting outside the works, attention turned to preparing more components. The curved door-capping which forms the edge when the door is lowered to become a loading ramp alongside a platform in a goods yard proved a particular challenge. A folded component, in close contact with the Oak, it was decided to make these from stainless steel. Finding a company able to bend these fairly long sections to the correct tightly curved profile proved challenging, and took us all over the country, and we are very pleased with the results from ADS Laser Cutting in Leicester. The tops of the doors then had to be machined and hand finished to match the steel profile.

The hinges, modified from spares obtained from a scraped wagon, have taken quite a bit of work to modify to fit this wagon. The Oak planks, having been test fitted and drilled then all had resin sealant applied to end grain and holes, and subsequently needed cleaning up prior to oiling.

May 2022

Whilst the wagon could be accommodated in the main workshop, work continues on the woodwork and metalwork. The photo shows how the inner corner plate is set up for drilling the holes through the timber planks. Unlike the "clips", these brackets are able to be based exactly on what is shown in surviving drawings.

April 2022

A group of us visited a Sussex sawmill and selected £2,500-worth of waney-edge air-dried Oak boards. Compared to purchasing ready-machined Oak planks this saved us half of the cost, and provided us with off-cuts which would be suitable for seating parts for our Southern Maunsell Restaurant Car 7864. The first photo below shows some of the boards, mostly around 15-ft long and up to 2ft wide, on arrival at Horsted Keynes.

Too large to be processed on our machinery inside the works, they were cut down to roughly the correct sizes outside with a skill-saw (photo right), and taken into the workshop and stored for a few weeks whilst we worked through the machining of the 40 planks to final size.

The final photo shows one of the 40 planks being machined to thickness on our planer-thicknesser, the third of five machining operations (following planing one straight edge, sawing to finished width, and then completed by cutting to length, and finally routing chamfers on some edges).

The first planks were test fitted just over a week after the raw timber had arrived.

This enabled the corner positions to be established, and the newly machined diagonal straps tested in position on their modified bottom brackets (now completed as per the drawing in the January report) over the following two days, so they could be measured for cutting and drilling to length.

Below we see the solution to the "clip" conundrum. It would make engineering sense for the solution to be the simplest and most elegant obvious solution, which we have assumed to be making use of existing bolts for the top and bottom planks to secure metal straps holding the planks in place. The arrangement does have the advantage of saving us a very significant number of stainless steel bolts (being used to avoid the problem of steel corroding badly when in contact with Oak). To prevent direct contact between the steel structure and Oak, and help preserve the structure for the future, roll Arboseal has been used everywhere where the two come into contact.

The mag-mount drill has been essential for so many operations on the steel frame, and here we see it drilling the corner holes.

January 2022

SR Bulleid Open Wagon 12058 has been progressing rapidly towards the finishing line. For the first time since possibly March 1975, 12058 has got wood fitted to it. Thanks to Richard for machining up all the timber, the team were able to fit the floor and drill the holes for the floor bolts. Where there are rivets and bolt heads on the underframe, we have had to carve out holes in the floor packers and floor boards so that they fit correctly (as per photo of Matt working on one of the packing pieces below).

You will recall that this wagon was built originally with thinner english hardwood. Thus the floor is spaced off the underframe using inch-thick packers.

Highly durable Iroko planks have been machined up from sawn stock in-house to save money, with the holes, ends of the timbers and floor packers sealed with an epoxy resin. We found some Iroko on 62002 from its overhaul in 2002 and it was like new, as compared to the softwood floor of that wagon which had rotted fairly quickly. Hopefully the floor in 12058 will last far longer with the additional protection.

The (unpainted) sides are much more visible, so it's been concluded that Iroko is not appropriate here, and a source of Oak has been identified.

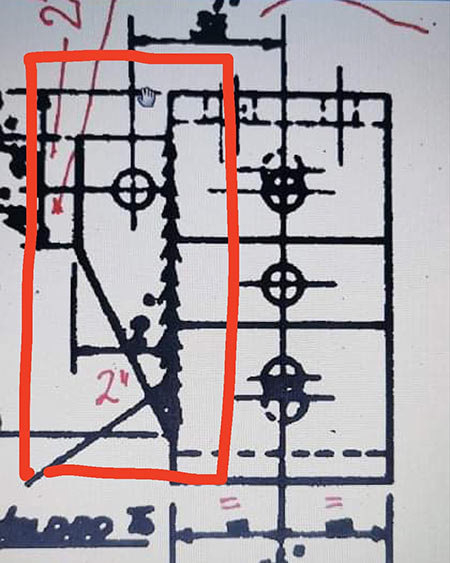

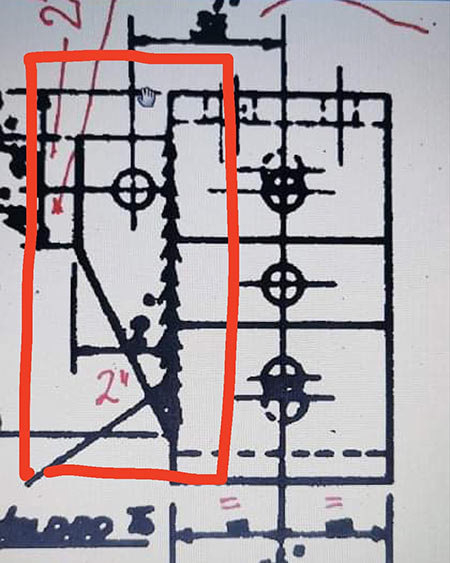

Matt has been busy on the Milling Machine making some new brackets for the diagonal straps to bolt onto, which is seen in this drawing. Once they have been machined up, they will be welded into position on the door-pillar brackets, as seen prepared for the weld below.

A third door hinge has been started by Laurie and is waiting final welding up.

November 2019

During the site clearance for and construction of the massive "OP4" sheds at Horsted Keynes, there was no working space for the project, which therefore halted. With the relaying of the yard in early 2019 work could recommence in earnest. In the intervening time the frames were frequently moved about, and this had taken its toll on the integrity of the paint applied some years ago. But during the year a new team has come together and work on the project has picked up rapidly where it was left off.

During the site clearance for and construction of the massive "OP4" sheds at Horsted Keynes, there was no working space for the project, which therefore halted. With the relaying of the yard in early 2019 work could recommence in earnest. In the intervening time the frames were frequently moved about, and this had taken its toll on the integrity of the paint applied some years ago. But during the year a new team has come together and work on the project has picked up rapidly where it was left off.

One task undertaken in the interim was the manufacture of a pair of glass-fibre reinforced resin "D" plates for the wagon, and on the right is seen the latex mould and a plate.

The underframe has changed colour many times this year but it is now a lot better looking than it was at the beginning of the year! It is currently waiting to be lifted back onto its wheelsets so further work can be carried out. The Bulleid Society have been kind enough to fund the material cost of restoration work to this wagon and we are grateful that they have done so.

The Wagon Gang has slowly been rekindled over the past year and is looking for new volunteers to help join them restore and look after the wagon fleet. We hope to bring back Goods Trains in 2020 and hopefully 12058 will be joining the set. If you are interested in joining the gang please contact Laurie or David Rhydderch.

The first photo below shows the wagon at the start of this year, and the second was taken in early November (both Laurie Anderson).

February 2013

2012 saw a great deal of progress on and off the wagon. Tom

Simcock and Martin Skrzetuszewski visited the Kent and East

Sussex Railway by arrangement, to measure up a similar SR wagon

that they have in their collection. This visit was necessary as,

although we have general arrangement drawings for the wagon, the

sizes of many components and hole spacings etc. are not marked on

these GA drawings. The visit was very fruitful and a lengthy

"chin-wag" with K&ESR C&W volunteers was enjoyed

afterwards.

Material was ordered to replace the missing sections of

bracket on the under frame; these brackets being the mountings

for the door and door pillars. The Tuesday Gang bent up the new

bracket sections to shape and welded them onto the existing

stubs.

Eddie Carter heats up one

of the door pillar brackets. This has previously been part-bent

to shape in the hydraulic press, but now is being bent to a

right-angle.

When the bend is hot enough, Andrew Breese

hammers the material to shape.

Doug Peskett then checks the bracket for square-ness.

This is the second bend going in. The material is heated to

red heat in the respective area before being bent.

(Click on each thumbnail for an enlargement)

The finished article.

The edges of the door pillar brackets have been

prepared for welding on by being ground at an angle.

The centre brackets are lighter and a different shape to the

other two. Having previously had the first right-angled bend

formed in them, the second angle is being formed by hand (with

the assistance of oxy-propane and a stilson wrench!).

The finished article.

The bracket sections are welded on after the existing stubs

have been ground to prepare them for welding. Some minor

adjustments had to be made on a couple of them to fit perfectly.

Here are the Tuesday Gang in action tackling the job - Eddie

Carter on gas (not shown), Andrew Breese on gas and welding with

Alan Wood and Doug Peskett on fitting and adjustment.

Andrew welded the brackets on down-hand. The underside of the

welds was finished by Bluebell apprentice James Parker.

Unfortunately, due to a misunderstanding (no one's fault in

particular - these things sometimes occur) the underside of the

top welds still needed to be completed but, to date, when the

opportunity to complete the job has presented itself, the weather

has prevented us from doing so. Even a light rainfall prevents

the welder from seeing the job clearly through the visor - Roll

on Spring!!!

Inside the shed, armed with a drawing and dimensions from the

K&ESR wagon, Eddie Carter and apprentice James Parker have

welded extensions on to the existing end tees.

April 2011

A refurbished drawbar was fitted to the south end by Paul

Hailes and Martin Skrzetuszewski, and 12058 was later moved to a

spot outside the paint shop.

The Eastleigh modifications involved removing several rivets,

welding a plate in the drawbar slot in the headstock and drilling

new fixing holes. These have been progressively undone, resulting

in what is seen here. The two pairs of three holes are for

rivets, the top ones having unfortunately been opened out to a

larger size. The hole for the drawplate has been opened up but

still needs some work.

The new drawplate is shown here test fitted. The holes were

drilled using the small radial drill at Horsted Keynes. One of

the ex-Palvan drawbars has been fitted, the drawbar collar having

been cut down to fit using the workshop’s mechanical

hacksaw.

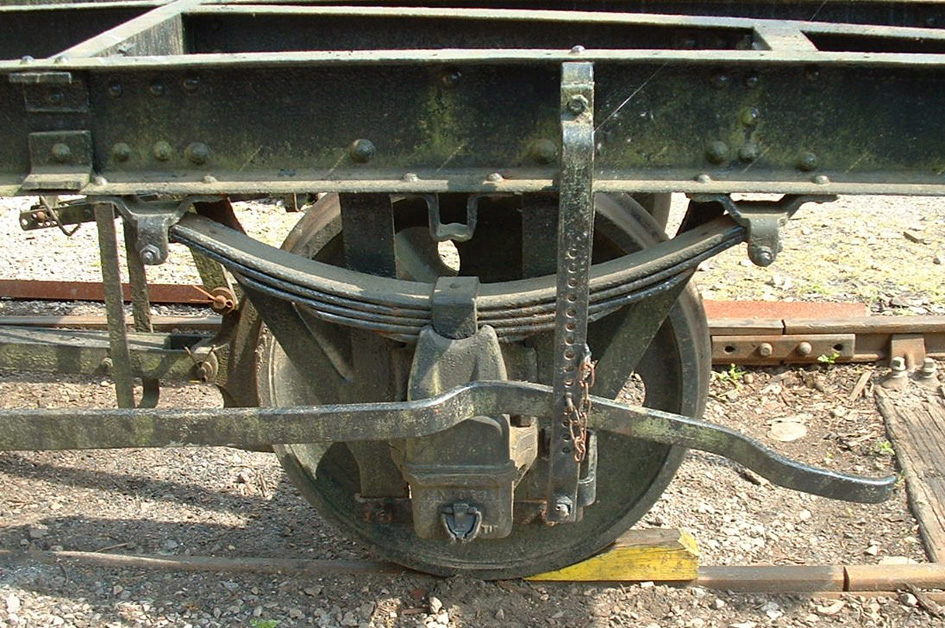

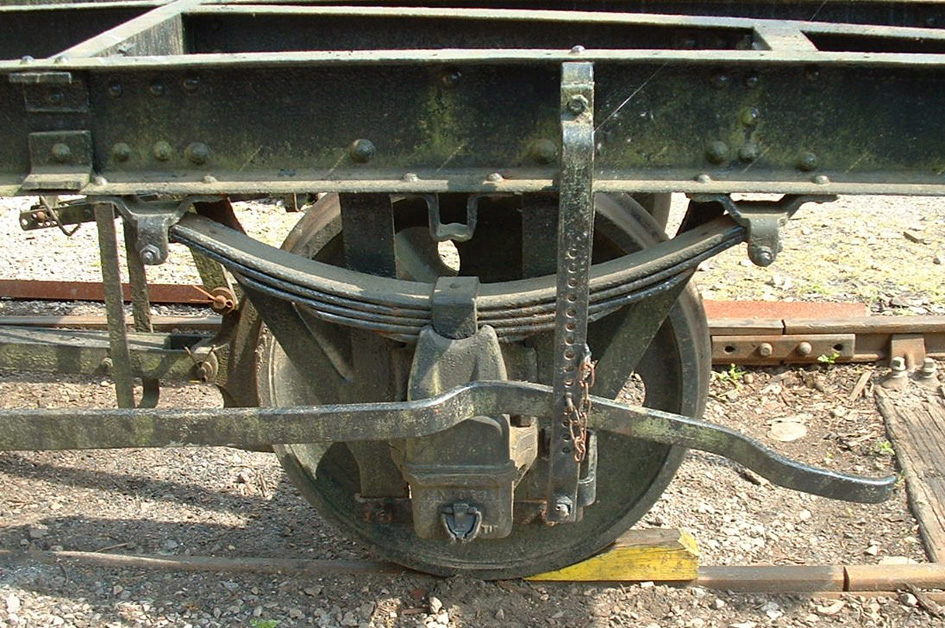

When the wheelsets were changed on 12058 it was hoped that two

of the original RCH type axle boxes could be recovered and

reused. The seal between top and bottom was made by a felt strip,

which fitted into a lip on each half of the axle-box. The lips

were prone to damage, and very few survive intact. This one is

OK.

It turned out that the RCH axlebox at the south-east corner

was not watertight, so Paul and Mark Hailes changed this one for

a BR pattern one.

March 2011

The drawgear was removed from the Palvan underframe by Tom

Simcock and the steel components were grit-blasted and painted by

Robert Macmillan and Ray Tanner.

The buffer rods and components were cleaned up and painted

(where appropriate) by Robert, Ray, David Chappell and Martin

Skrzetuszewski.

A drawbar, nut and collar after grit-blasting. In the

background leaning against the wall are end tees for GW 87782 and

12058. On the floor are two buffer castings for GW

87782.

The two drawbars after painting. In the

background is the BR1 bogie on S16210.

12058 in the C&W Works F-road, having been fitted with the

refurbished buffing gear. The south end drawbar seen here

sustained damage at Eastleigh, and will be replaced in due

course.

February 2011

12058 was rerailed yet again in late February and placed on

F-road, which is a very tight working space. The buffing gear was

removed from the Palvan underframe by Robert Macmillan and Martin

Skrzetuszewski.

The damaged end stanchions were straightened and repaired by

Eddie Carter and his colleague Doug Peskett.

Two of the four buffer rods, as removed from the Palvan

underframe, can be seen in the photo on the right.

2010

The underframe of 12058 was rerailed and the damaged end tees

were removed for straightening by volunteers.

The Palvan reached the south end of the yard at Horsted

Keynes.

Copies of SR mechanical drawings for 12058 were supplied by

Martin Allen in May.

In June the Palvan made it to the carriage works and its body

was removed prior to the recovery of the buffing and drawgear.

However, both it and 12058 were then derailed to make room for

the 50th Anniversary displays in the down yard at HK.

2009

Still no sign of the Palvan (the source of replacement buffing

gear for 12058) and no sign of any repairs happening to the end

tees of 12058. At the end of the year, at our instigation, an

agreement was reached with the manager under which we would

repair the damaged tees and the underframe would be rerailed in

the new year.

2008

In May/June 2008 the wagon gang had been tasked with the

overhaul of LMS medium goods wagon 474558. As this wagon had been

withdrawn from the engineering fleet and was now designated as a

heritage wagon, it was agreed that it would be reverted to its

original condition. Part of this process involved replacing the

present BR self-contained buffers with 13 inch diameter spindle

buffers with rubber recoil sets. It was intended that these would

be removed from a BR Palvan that was allegedly being emptied at

Sheffield Park and would shortly be worked up to HK for

dismantling.

We were informed that the van’s arrival would definitely

be within a fortnight, so we decided to remove the buffing gear

from SR 12058 and fit it to LMS 474558, replacing it with that

from the Palvan. Needless to say, the van did not arrive within a

fortnight: in fact it took some 18 months to get to Horsted

Keynes! In the meantime it was found necessary to derail 12058

and, in a subsequent move by paid staff, the tees at one end were

severely damaged due to misuse of the Loadall. We were told that

they would be repaired.

On the positive side, a replacement drawplate for 12058 was

made (courtesy of the Bulleid Society) for the north end, where

the original had been removed during the Eastleigh Works

conversion. The original was a forging but the replacement was

made, through necessity, from steel plate, commercially cut to

size and shape. The components were welded together by Steve

Rogers as a volunteer job.

2007

Once the underframe was back on the rails, giving access to

the arc welding set, many of the extraneous holes drilled or cut

into the underframe at Eastleigh during the adaptor wagon

conversion were welded up. A set of four buffer rods with 13 inch

diameter heads, and two sets of rubber springs, were fitted.

These were removed from an SR open wagon purchased for spares

from Bristol Docks in 1981 by Martin Cresswell.

December 2006

The overhaul of the underframe is now pretty well advanced,

and the steelwork being made for the body of the wagon is

starting to be erected.

July 2006

Work continues on the brake gear and steelwork for the

reconstruction of the body.

March 2006

Following the arrival of this wagon underframe from Eastleigh

Works, all the internal user modifications were removed. The two

missing RCH pattern buffer castings were replaced using two

suitable spares that wre on site. The open-spoke wheelsets were

swapped for two of the correct disc pattern (standard by the time

this wagon was built) using one of the portable A-frame hoists

and the ever-versatile JCB Loadall.

Bulleid Society members, taking time off from working on

34059, have made significant progress on needle-gunning and

painting the underframe and running gear of the wagon, using

paint funded by the Society. However, progress came to a

temporary halt in December when it became necessary to chip the

ice off the underframe before work could commence!

Before and after... A new door pillar made from a SR bogie

component.

Little is wasted, as the brackets are saved to be used

on other SECR wagons.

During the autumn the handbrake pushrods were overhauled and

refitted, the rotten and split timber packing pieces being

replaced with new. Four suitable second-hand end tee irons were

identified on site at Horsted Keynes. These were gas-cut and

ground to the correct profile and will be ready for fitting

shortly. Four lengths of steel angle from scrapped SR coach

bogies were also identified on site; these have been sawn to

length, gas cut to rough size and profile and ground to the

finished profile. After drilling, and the fitting a door securing

post, these will also be ready to fit. There is still some work

left on the underframe before these components can be attached.

Several missing rivets (removed as part of the Eastleigh

modifications) have to be re-fitted and some redundant holes

(from the same) have to be welded up.

July 2005

The underframe of 12058, having had internal-user

modifications removed. Richard Salmon

See the main web page for 12058.

Return to BRPS Home Page,

to the Timetable or to Special

Events

Goods Division: Home - Shop - Projects - Instagram - Flickr - Facebook - Donate

Carriages & Wagons -

Intro -

Development -

Stock Lists: Carriages, Vans, Wagons & Multiple Units -

Carriage Fleet Review -

Join us

C&W Works News - SR Coach Group - Goods Division -

Operation Undercover -

Carriage Shop -

Technical Pages

Visitor Info. -

Museum -

Trust -

Catering -

Contacts -

What's New -

Projects -

Locos -

Carriages & Wagons -

Signals -

History -

Other -

Links -

Search -

FAQ

Why not become a BRPS Member? -

Get more involved as a Volunteer

Your ideal Film/TV location?

Text © Martin Skrzetuszewski

Text © Martin Skrzetuszewski

Photos up to 2013 © Martin Skrzetuszewski , and more recent ones by Richard Salmon, Laurie Anderson, Jack Gregory and Matt Lander.

Page created by Nick Beck, 19 March 2006. Last updated by Nick

Beck on 15th February 2013 and Richard Salmon, 9 March 2023.

© Copyright BRPS. Privacy Policy

|