Carriage & Wagon Dept -

Stock Lists: Carriages, Vans, Wagons & Multiple Units -

C&W News

SR Coach Group - Goods Division -

Operation Undercover -

Technical -

Join us

Carriage & Wagon Works News

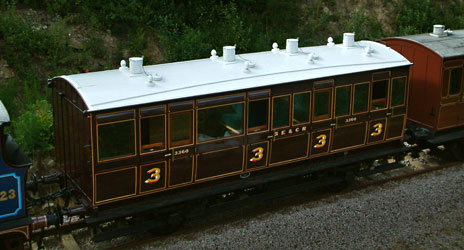

LCDR No.51 - SECR No.3360

Restoration and conversion as a carriage able to carry passengers in wheelchairs

The "People's Millions" LCDR coach (SECR 3360) emerges from the paintshop (Andy Prime).

The photo on the right shows the coach, finally complete with the last of the lettering, the lining on the ventilator bonnets and now fully varnished, being shunted over the pit for final mechanical adjustments.

Having been voted funding for the project by "The People's Millions", part of the Big Lottery Fund, work started on the project once the carriage was moved into the shed in the New Year of 2010. The plan included the conversion of the brake area and adjacent compartment into a small saloon, using the double-doors to provide wheelchair access. The two compartments at the north end of the vehicle have been restored to original condition. In line with the long-term plan for the Bluebell's LCDR carriages, it is restored in Edwardian SECR purple lake livery to match our SECR P-Class locomotives.

Having been voted funding for the project by "The People's Millions", part of the Big Lottery Fund, work started on the project once the carriage was moved into the shed in the New Year of 2010. The plan included the conversion of the brake area and adjacent compartment into a small saloon, using the double-doors to provide wheelchair access. The two compartments at the north end of the vehicle have been restored to original condition. In line with the long-term plan for the Bluebell's LCDR carriages, it is restored in Edwardian SECR purple lake livery to match our SECR P-Class locomotives.

Dave Clarke's flickr site features the overhaul of this carriage in further detail (although now missing the earlier photos from fotopic), and Dave supplies most of the photos included here.

26 May 2011

This was the date for the launch into service of the Big Lottery Funded (People's Millions) coach No.3360. The morning saw speeches and special guests (including Paralympian and East Grinstead resident, Richard Schabel).

The restoration and conversion work saw about 50 volunteers and staff spending a total of 8,500 man and woman-hours on the project. On top of the £49,500 of Big Lottery funding, our volunteers contributed about £100,000-worth of volunteer labour.

Alex Morley provides the photo on the right, and also pictures of the run with 3360 on flickr.

John Sandys' provides a photo of the launch train at Horsted Keynes, and video of the launch train leaving Sheffield Park at 12.35.

The photos below show Paralympian Richard Schabel cutting of the ribbon (Mike Hopps), boarding the train (Derek Hayward) and 323 "Bluebell" with the three 4-wheelers (Andrew Strongitharm).

More photos below, from the launch day. Note the oil-lamp "chimneys" and the bungs on chains which replace the lamps when removed, and the "Eros" ventilators, distinctly different from the near universal "Torpedo" type (David Chappell). The second shows those of the restoration team who were able to attend in the afternoon (Jon Bowers).

The day before the launch saw a brief test run, and with the weather holding, this photo shows Stuart Fielder completing the lettering that evening - a lot of work was done in the last few days to prepare for the official launch!

The first photo below shows Stuart and Tony Clements working on it, as it's coupled to the other two 4-wheelers in the platform at Horsted Keynes that evening.

Kevin McElhone's photo below shows Richard Salmon explaining the restoration of SECR 3360 to a guided tour party at the Open Days the previous weekend, whilst Deborah Salmon and Ed Owen do some final cleaning of the windows.

6 May 2011

Apologies for the delay in producing another update, that is down partly to everyone working flat out to get the carriage finished (the requirement from the lottery was that we spend the money within 12 months, which we've done) but there is a real requirement to get the carriage into service, and this will be achieved by the end of this month. The other reason is the disappearance of the fotopic.net photo site, robbing us of Dave Clarke's pictorial record of the project. We hope to recover that situation, and Dave has now started to put some photos up in a flickr photo set.

Dave's first photo here shows the carriage being shunted into the paint shop on 9th April, and those below show the other side of the carriage, lagging slightly behind, and the interior of the wheel-chair accessible saloon, and a compartment - all seating and internal fittings now being complete.

A particular point has been made of using historic material in the creation of the interior of the saloon. All the internal teak panelling at head height, plain panels, the slatted ventilators, and their cover/cutout panels have been made using teak panelling salvaged from the external panels from this coach, plus a couple from panels removed from the Bluebell's Metropolitan Railway carriages during their restoration. In each case the original panels were split but these smaller components could be cut from that part which remained in good condition.

Dave Clarke's photo on the left shows the coach on 10th April, one day after entering the paint shop. Part of the coach which is in final topcoat, seen here with the lettering and lining just started - a narrow vermillion line has yet to be added, as has the shadowing and blocking on the lettering, of which there will be more to come. Until the lining around the ventilator openings is completed the vent covers (which themselves have detailing picked out with lining) cannot be fitted.

David Chappell's photo below taken a week later shows the great progress in that time on the West side; concurrently the East side was brought up to final top-coat and the ends varnished, whilst the last work continued on door locks and final interior details.

Dave Clarke's two photos below show the stage reached another week later.

Click on any photo in this report for an enlargement.

This next sequence of photos from Richard Salmon shows how one particular replacement part for the carriage was made from second-hand salvaged teak. The part in question is the moulded horizontal bar which sits between the slatted ventilator at the top of the door, and the droplight below (seen with its bi-lingual enamelled sign in place). The droplight is installed by sliding it into the top of the door, when the door is open, down the groove which continues to the area where it normally sits, and this bar is then screwed into place to prevent it rising back up the groove.

The timber used to make these bars was some offcuts of teak about two-foot long and just over an inch thick (first photo below), provided by a Bluebell member, who was keen to know how we would use the timber, so this sequence shows that!

The second photo below shows the timber roughed out using the tilting table on the band-saw, to make the most economical use of the timber.

The complex series of curves were then cut using three different shaped router cutters on our table router, and then finished by hand and varnished. In addition to the 8 we needed for this coach, the K&ESR are restoring another similar coach, so we asked them if they needed some, and hence 12 were also made and supplied to them free of charge, a quid pro-quo for assistance they've given us with the guttering - in the global scheme of things this cooperation makes a lot of sense, because the largest part of the time taken to make them is working out how to do it, and setting up the machines to make the various cuts.

18 February 2011

Another report with photos thanks to Dave Clarke:

January 20 marked the first anniversary of the project with the coach being placed on its underframe and brought into B Road in the old shed. 3360 has developed a reputation for being a snow maker. Heavy down falls in December 2009 and January 2010 had cut off access to Horsted for the first time in years and thereby delayed the start of the project by a month. Further snow falls in December reduced access to C&W to a bare minimum for a further couple of weeks.

Roof

The curved patrices have been fitted to the ends of the roofs and has enabled the grab handles to be fitted. Together with the curved handrails, these help provide safe access to the roof. Screw holes have been filled and treated with undercoat. Last weekend saw the first topcoat applied.

Stepboards

These have been fabricated and fitted to the underframe. The lower boards have received their first overall coat of black gloss. They await the final topcoat to the upper surface which will also include sand to produce an anti-slip surface.

Coach Electrics

The internal wiring has now been installed within the coach body. There are two lighting circuits to each of the four ceiling roses. The cable circuits pass down within the northern end of the coach and connect with the underframe runs. The battery box has been installed and connected to the cable runs and the control box. The photo below shows an electronic version of a regulator to govern the circuits.

The trunking for the RCH run is being installed - jumpers link the coach electronically to its neighbours.

Compartments

Once the upper floorboards had been fitted they received coats of primer and undercoat before a topcoat of 'Totally Cocoa' dark brown gloss. The seats backs and bases have been installed.

A central leg supports the middle of the front rail, as seen above.

Saloon

Saloon

The partitions have been grain painted and the first coats of varnish applied to the southern end. The luggage rack has also been fitted to the northern end (photo above).

The seat at this end has been trial fitted and then removed so that the final coats of varnish can be applied to the framework.

The upper body panels above the side lights, which in the compartments are scumbled pine, have been replaced with a series of ventilators. These comprise hit & miss boards and fascia surrounds and have been fabricated from recycled teak panels removed during the early stages of the restoration and some left over from the Metropolitan coaches (photo right).

Doors

Structural Repairs to the ten doors have been completed and they have been fitted to the coach and only Door II (first photo below) awaits its panelling [now fitted].

The four compartment doors have received finishing touches such as the unusual brass match strikers. They still require some signwriting and final varnishing.

Unlike the compartment doors which have been lined with original teak panelling and mouldings, the six doors in the saloon are being fitted with new teak mouldings. The four brake / luggage doors were originally lined with painted pine but as they are now part of the saloon, it was decided that these should be replaced with varnished teak fittings to match the northern end of the saloon.

The first five droplights have been installed in doors III, IV, V, VII & VIII - the other five have received three coats of varnish and should be fitted shortly.

Exterior painting

In order to allow the steps, handrails, comms gear etc. to be fitted, it has been necessary to complete paintwork first. This has focused up on the application of brushing filler and undercoat to the mouldings to bring them up to the same level as the panelling.

This process has culminated in the application of the first coat of purple lake gloss. The mouldings were painted first and 3360 briefly carried a North Staffordshire Railway form of livery (above left).

Purple lake is a colour that changes with the angle at which the light shines and can vary in appearance from red to brown.

The painting of the ventilator bonnets is progressing separately, since they cannot be added to the vehicle until the area around where they go has received several top-coats and the full lining applied, since the lining extends under the bonnets.

1 February 2011

Dave Clarke's photos illustrate see state of the carriage as of 23rd January, and then the new teak panelling on the interior of one of the original guard's luggage doors. Originally panelled in soft wood, the door has been rebuilt to match the passenger doors, since it is now in the saloon area. The final photo shows two of the four seats now completed. The coach also now has 5 of its six luggage racks in place.

12 January 2011

These photos from Dave Clarke show some of the progress over the last two weeks on SECR 3360. That on the right, and the first one below show the oil-lamp chimneys, rain-strips and gutter edging in place on the roof, and the last of the windows, and all the quarter-light external window-framing fixed in place. This side of the coach is now not far from having its mouldings fitted, to bring it up to the same state as the other side and the two ends. The areas of the coach still with brushing filler to be rubbed down and then undercoated can also be seen in these photos.

The middle compartment now has one luggage rack, and communication-cord tubing in place. This luggage rack is screwed through the partition into the backing board of the one in the adjacent compartment.

The upper layer of the floor has now been laid in the middle compartment. The central section will be finished with a clear sealant, whilst that part under the seats will be painted.

The seat base structures in the end compartment are almost complete, with just the centre-supports to be put in place.

Two of the four doors from the former guard's compartment are at an advanced state of repair; they are also being panelled internally in teak so as to match those in the remainder of the coach. The repaired bottom-side in the door opening on the east side has been rebated and had the original steel tread-plates re-fitted.

The internal bodyside panelling in the saloon is now complete, and has received nearly all of its daffodil undercoat in preparation for scumbling, and most of the teak sections have had their first coats of varnish. Both compartment ceilings have been fully painted, and the saloon ceiling only now needs one final coat of Farrow & Ball "New White" top-coat.

Tom Simcock has, with Roger Barton's help fabricated the two sets of running-boards for each side. The upper butts up to the sole bar while the lower ones require an upright at the back to prevent feet slipping off the back! They have been trial fitted and painted to top coat on their undersides.

More of Dave Clarke's photos taken on 8th January are on his photo album for the project.

29 December 2010

Work slowed slightly in the run-up to Christmas due to the road conditions, but this was the one project in the carriage works still making significant progress in spite of the difficulties of the snow, ice, and lack of heating in the works (which reminded us that it was only 16 years ago that we finally got doors on the carriage shed!).

Several of the doors have now received the coach running number, but not compartment letters, since there is no evidence of these ever being carried. The state of the west-side compartment doors, one with internal cladding completed, is seen in this photo from 21st December.

The remaining photos below were taken on 29th December. The first shows the second luggage rack fitted in the northern compartment

The middle compartment is now complete in terms of paintwork (a luggage rack has since been fitted in here).

The saloon interior is also seen, where the last of the internal cladding has been fitted, but not yet fully painted.

The top surface of the floor (this top layer being re-used timber from the coach's original floor) has been laid in the northern compartment (and that in the middle compartment is ready to be laid).

Dave Clarke also has some other photos taken in the last couple of weeks.

12 December 2010

Dave Clarke has some more photos:

On Sunday 12 December, the coach returned to the dock following its visit to D-road and placement upon its underframe, and is seen outside in the photo on the right during the shunt.

The roof pots have now received three coats of undercoat and are ready for a couple of coats of gloss paint. The photo shows them in primer (red for steel and etch-primer for the brass fittings).

Structural repairs to the eastern inward opening guard's door (Door I) have been completed and it has now been hung.

The six seat backs have now been completed and the trimmers have moved onto the second seat base.

The Big Lottery Fund has created a series of galleries featuring their projects in the South East including a selection of photos of the work on 3360

28 November 2010

Dave Clarke's photos:

Dave Clarke's photos:

Four oil pots (chimneys) have been fabricated for the roof.

The first of the interior panelling and mouldings for the doors have been cleaned and revarnished.

Door V's panels have been fitted and sign written with a large "3rd", as seen in the photo left.

The scumbling in the northern compartment has been finished and the partitions have received four coats of varnish. This has enabled the first of the luggage racks to be fitted

br>The poles and battens for the other five luggage racks have been varnished and await construction.

Quarter panels should have been fitted in the second compartment the following week but the snow delayed this until the weekend, so the scumbling has had to wait a few more days!

The floors are nearing completion following the laying of the 1"ply lower floor in the second compartment and saloon. In the compartments these will be covered with the best of the original floor boards while the latter will be covered with lino.

9 November 2010

More photos:

- Door V has been hung on the east side of the northern compartment so that all three of the 'old' compartment doors are now in place on that side.

- The inner mouldings and panelling lining the doors were removed several months ago and the first of these have been cleaned and repaired. With the completion of Door V and the first seat backs it has been decided that the inner door fitting should be varnished and refitted. These have been treated to two coats of shellac and a 50/50 coat of varnish.

- Over the last week, the trimmers have completed the first seat base and a second back - the later has been reduced in width by about half an inch and is a much better fit than the first. The comfort of the seating matches that in brake second LCDR 106 which was later downgraded to third class as 114. When we trim our next project, LCDR five compartment third 668, the seating will be far more austere!

- The first brass threshold strips have been fitted in the compartment doorways. They received a coat of etch primer before the madder undercoats and then sealed in with mastic and brass screws.

- The mouldings have been fitted around the two large saloon sidelights or windows on the western side and the screw holes filled. Primer and a madder undercoat was applied to these, the upper parts of the door frames and the underlying waist panels. These panels were cut from the larger original lower teak panels and have had a thick layer of brushing filler applied to fill the grain. This was then flattened back such that it performs its purpose of filling the grain and other blemishes.

- The western quarter panels and both partitions of the northern compartments have been grain painted. This is the process by which softwood is painted, in this case, to resemble oak. The daffodil undercoat is painted with a mix of scumble glazes and carrier dilutant. After being applied, the glaze is then drawn with combs and rockers to produce a grain like pattern. This is then softened with a badger hair brush and a rubber to produce a quarter sawn appearance. The resulting matt surface has now received two coats of varnish.

- The waist rail mouldings have been fitted to the saloon - the last on the west side of the body.

- On the underframe, the fitting of the steam heat and vacuum pipes is nearing completion. These grey pipe can be seen running through, and crossing over in, the centre of the frames. The rectangular grey pieces of steel on the headstock are to help reinforce the bolts securing the wooden coach body to the steel underframe. Also in grey are part of the metal work for restraining the disconnected vacuum and steam hoses and the position of the patrice for through lighting control cable.

The photo above shows the carriage on its new underframe.

17 October 2010

More from Dave Clarke showing the weekend's work:

10 October 2010

This photo illustrates progress, with a fourth door has been hung, and mouldings and quarter-light (window) frames fitted on part of the exterior. This is the other side of the coach from the photo last week.

Dave also has another photo, showing the prototype seat back test-fitted.

3 October 2010

This photo shows the East side of the coach with the gutter now in place, following the canvassing of the roof. The saloon windows have all now been formed, and glazed, and several of the doors fitted.

More photos showing progress on:

25 August 2010

This photo shows the completion of the structural work at the saloon end, and the cladding progressing well on the compartments.

This photo shows the completion of the structural work at the saloon end, and the cladding progressing well on the compartments.

In addition:

The underframe is nearly completed.

The roof boards have had a channel routed in them by David Chappell to accommodate the electrical wiring for the lights;

The panelling has been fitted below the new saloon sidelight on the west side, and the surrounding teak framing has received its first coats of goldsize and varnish;

The ceiling in the northern-most compartment has received its first coats of topcoat.

6, 9 and 11 July 2010

The photo on the right shows recent progress, where the first of the four saloon windows has now been formed in the former brake end.

The other end of the coach (two compartments) is now structurally completed, and has been re-clad, and the second overhauled door has been re-hung, as seen below:

Some work however remains to be done to create the new structure at the saloon end on the East side.

The prototype droplight has been made (10 are required).

The repairs to the roof have also been undertaken over the last few weeks.

Painting the carriage is an on-going process - here we see, following priming and undercoats, a layer of brushing filler which has been flatted down to form a smooth surface, filling the grain of the timber.

The space above the new saloon windows will be taken by ventilators, as was usual for LCDR saloon designs. Here we see the surround for the hit-and-miss ventilator test fitted.

Dave Clarke has many more photos showing progress on the project, here.

20 June 2010

The plywood end panelling has received its first grey undercoat, and the first (madder red) undercoat has been applied to the sides.

The plywood end panelling has received its first grey undercoat, and the first (madder red) undercoat has been applied to the sides.

Dave Clarke's other photos show:

3 May 2010

This photo shows the teak framework stripped back to bare wood. This part of the frame forms the outside of the coach, with the final finish built up on it, so has to be carefully prepared.

This photo shows the teak framework stripped back to bare wood. This part of the frame forms the outside of the coach, with the final finish built up on it, so has to be carefully prepared.

The internal boarding on the end of the compartment is starting to be fitted, and the access point for the electrical terminations can be seen in the centre (where it will be covered by the seat).

18 April 2010

More photos showing, on the right, the new plywood cladding on the completed north end of the carriage, and below preparations to shorten the underframe, with some of the rivets removed.

21 March 2010

Here we see Stuart Fielder working on the new teak framework replacing that removed when a fireplace had been built during the coach's days as a bungalow. Note also the gap left in the body-side by the removal of the Guard's ducket (projecting lookout).

Below is the removed ducket and draught screen from the guards van (that on the other side had been missing in any case). These have been stored in LCDR coach 48, since these items are missing from that vehicle, so will be useful if/when that carriage is eventually restored. Also a smaller fireplace was cut in the side at the north-western end, and the repair seen below was made to deal with that alteration.

6-9 March 2010

More photos from Dave Clarke, showing that the carriage has now moved into main workshop at Horsted Keynes.

The photos below show more evidence of livery, the lining around the quarter-lights (windows) and an area of the ventilator hood now cleaned to show, above, the post-WW1 brown, and below, the deep lake and associated lining, carried before WW1. The green and white paints date from the domestic era as a bungalow.

28 February 2010

The photo on the right shows a repair to the north-east corner of the bottom-side structure, and the bracket with goes around the corner, covering over most of the repair. It also shows the "new" waist panel, part of the mahogany panelling which was elsewhere on the carriage, cut down from a larger panel which had split.

The photos below show 3360 alongside 114 again, just 40 days after the previous such photo, and also door VIII, stripped revealing the SECR lettering "3rd" and "3360". It is interesting to note that a couple of the door panels had clearly been replaced with new timber later in the carriage's existence. Tracings of the lettering have been taken to enable the exact reproduction of the signwriting, since is this period to which the restoration is aimed.

7 February 2010

This week saw a major advance, with further stripping of the vehicle and the first repairs undertaken. Dave Clarke's photos and report cover the work undertaken.

Further paint striping of the eastern side with hot air guns and paint stripper has revealed a paint sequence down through the layers, from domestic green and cream, through early SR green, late SECR brown, and possibly two layers of crimson lake. Also included within this sequence are a series of undercoats.

The SE east corner pillar revealed tantalising glimpses of straw yellow and vermillion lining to the lower of the two crimson lake coats. This was echoed on Door V which has been fully stripped. As a result, a paintakingly careful stripping of door IV has revealed the crimson lake and lining in its glory, as seen in these two photos.

Each of the three layers of the ventilator bonnet was painted with adjacent lines of straw yellow and vermillion. The same was also revealed on the door styles and cross members surrounding the bonnet and droplight. A 1/2" straw yellow line was applied to the crimson lake 1/4" from the edge before the outer edge was then over painted with a 1/8" vermillion line (leaving a 3/8" straw line).

There are several key tasks to be undertaken during 3360's restoration, of which repairing the northern end is probably the major one. This end had been removed after the coach has been grounded as part of a house, in a order to extend the size of the room comprising the two compartments. The original end was placed further away from the coach and new wall sections inserted to extend the length of the room. On recovery in 2003 the original end section was recovered and brought to the Railway inside the coach body.

On the removed end, both ends of the three horizontal frame members and the lower ends of the five verticals had been cut close to the tenons. In order to ascertain what repairs were required the end framing, which had been shorn of its cladding last week, was offered up to the hole.

A gap was found between the corner pillars and the end of the ends of the frame work. Measurement of the vehicle showed that the external width across the brake end and the remaining partition was 8'. However across the north end it was 971/2". The spreading of the corner pillars had also seen a drop of about 1 to 11/2" in the centre of the roof. A couple of acro props were used to gently ease up the last two roof hoops and a clamp applied across the corner pillars to bring them back to 96".

The gap between the corner pillars and the ends of the three horizontal members of the end frame was then measured so that new extensions could be made. These are in the form of a cross, the two ends of which form tenons; one for the door pillar and a second for the frame member.

With the end still supported in place, the two screws securing each joint holding the three horizontals in place were removed - most came out without too much bother. After a little heat they all came out with only one breaking off.

The remaining frame work was then removed and four new extension plugs slotted into the corner pillars. The two beams were then dropped in place so that the "mortises" or slots cut in the ends of the cross members fitted around the "tenons".

By the end of Sunday, two horizontal members were back in place, together with the western most of the verticals. The joints are currently only held together by screws. In due course the new joints will also be stuck with a water repelling, expanding polyeurathane glue, and the ones into the corner pillars bedded in mastic (where the railways traditionally used a lead-based paste).

Short lengths of offcuts of teak have been machined up on the table router, to prototype the replacement body-side mouldings and the side-light (window) frames, to confirm that the cutters we already have are suitable. The required lengths will be run off once suitable teak boards are to hand.

The next jobs will be to continue refitting the northern framework, strip the remaining paint from the "quarterlight" face of the NE & NW corner pillars and the rebated roof hoop before the missing partition is fitted and while access is relatively easy!

31 January 2010

On 20th January, after the snow had abated, we were at last able to crane the body of LCDR coach No.51 onto its temporary underframe. Another underframe is to be shortenned to carry the coach. It is seen here next to our current pair of restored Victorian 4-wheel carriages, LCDR 114 and LBSCR 661.

As can be seen, the north end is missing, but was recovered along with the rest of the body back in 2003. The photos and details of work carried out to date are provided thanks to Dave Clarke.

Now that the coach has been brought into the north end of B road in the shed, work has begun on its restoration and transformation into SECR No.3360. Over the next year we hope to keep this page up to date with the progress being made on the conversion and restoration work.

Over the last week and a half the following work has been carried out:

The majority of the domestic modifications have been removed.

A start has been made with the hot air gun and paint stripper to remove the layers of paint from the lower east side exterior panels and the teak framing. Externally, the paint coats include domestic green and cream, SECR maroon and possibly varnish. Internally the frames were possibly varnished before receiving a thick white / cream base coat and scumbling. They were later painted blue and pink in domestic use.

The quarter-light (window) mouldings have been removed from the east side which has allowed the 1/4" thick glass to be removed.

The waist and upper body side panels have been removed. They will be replaced with marine ply or teak salvaged from the north end.

The cladding has been removed from the northern (compartment) end, the end which had been detatched when the house was extended in domestic use. Some of the external teak cladding will be saved for reuse later in the project. The stripped down north-end frame is seen above.

The NE corner bracket / strap has been removed. This involved the use of heat and a drill to cut the heads from the screws and coach bolts. They will need to be drilled out with a corer.

The interior teak panels of doors IV & V have been stripped. The doors are numbered around the coach from the SE corner and as a result the V is in the NE corner, VI the NW and X the SW door of the brake. Both IV & V have a large 3RD visible on boards 2, 3 & 4 (numbered from the top). Board 1, below the garnish rail, is plain teak as are boards 5 - 7. On door IV boards 5 & 6 are softwood which suggests that the door was repaired following damaged in service. (It appears possible that the east side received a side swipe and consequent repair at some time in the coach's history.)

The softwood internal cladding around the quarter-lights has been removed (below) and will be replaced with new. Some of the brackets which strengthen the upper-body joints have been removed, grit-blasted and given two coats of primer. The photo also shows that some minor repairs are required to the adjacent corner pillar where the end had been removed, but generally the structure of the coach is in excellent condition.

Dave Clarke's flickr site features the overhaul of this carriage in further detail (although now missing the earlier photos from fotopic).

See also the web page for this

carriage.

Return to BRPS Home Page,

to the Timetable or to Special

Events

Carriages & Wagons -

Intro -

Development -

Stock Lists: Carriages, Vans, Wagons & Multiple Units -

Carriage Fleet Review -

Join us

C&W Works News - SR Coach Group - Goods Division -

Operation Undercover -

Carriage Shop -

Technical Pages

Visitor Info. -

Museum -

Trust -

Catering -

Contacts -

What's New -

Projects -

Locos -

Carriages & Wagons -

Signals -

History -

Other -

Links -

Search -

FAQ

Why not become a BRPS Member? -

Get more involved as a Volunteer

Your ideal Film/TV location?

Last updated 15 July 2011 by Richard

Salmon

Last updated 15 July 2011 by Richard

Salmon

© Copyright BRPS. Privacy Policy

|