Carriage & Wagon Dept -

Stock Lists: Carriages, Vans, Wagons & Multiple Units -

C&W News

SR Coach Group - Goods Division -

Operation Undercover -

Technical -

Join us

Carriage & Wagon Works News

GWR 5-plank Open Wagon No. 87782

A Veteran of the Great War!

Restoration Progress Report

Current situation - March 2022

The rebuilding of this wagon is currently on hold, for two reasons.

Firstly, when the ground behind the carriage works was cleared to build OP4, there was no space available to continue with the work on this wagon. Secondly, once work on wagons resumed under the auspices of the new Goods Division, it was obvious that it made sense (for reasons of project timescales, space, available engineering effort, and money) to concentrate on only one major wagon rebuild at a time (alongside quicker intermediate overhauls and repaints).

The reconstruction of SR Bulleid Wagon 12058 was chosen to be progressed, and consequently this project continues at present to be mothballed. We do hope to be able to return to this project at some point in the future.

Just to recap, the Bluebell Railway Trust has agreed to hold donations from individuals towards the restoration of this historic (albeit

non-SR) wagon. All work is being undertaken by volunteer members of the BRPS. By September 2009 it was clear that we were more likely to

raise the money for the project than not, so with a few hundred pounds in the kitty and work on LMS medium goods wagon 474558 drawing to

a close, we requested that GWR 87782 be brought over to the down yard at Horsted Keynes so that we could commence work on it.

If you would like to support the work on this wagon, you can give to the Bluebell Railway Trust online

using your credit or debit card, through the Charities Aid Foundation, which reclaims the Gift Aid on our behalf. To donate through

this to the GW 87782 project, there is provision for adding a note to that effect.

If you donate directly to us, and give

£25 or more and are a UK taxpayer, the Trust can recover the income tax you have paid on your donation if you complete a Gift Aid

form. Gift Aid/Donation forms are available on-line here or from:

The Bluebell Railway Trust,

Sheffield Park Station,

Nr Uckfield,

East Sussex

TN22 3QL

Cheques payable to The Bluebell Railway Trust should also be sent to the same address. Please indicate that you wish your donation to

be put towards the GW 87782 project.

Please note that to keep costs down acknowledgement of donations to the Trust will not be sent unless you include a stamped addressed envelope.

Thank you for your support,

Martin Skrzetuszewski and the Horsted Keynes Volunteer Wagon Gang.

October 2014

2014 has not been a good year for 87782's restoration, with illness and other projects reducing the number of man-hours spent on it.

Despite this, the modified headstocks were test-refitted earlier in the year. Additionally, the inner headstock brackets (manufactured at

Bristol Docks when the then new headstocks and Dowty buffers were fitted) have been marked up and chain-drilled to clear the large nuts

on the back of the buffers (original circa 1911 GWR pattern) that we will be fitting.

The underframe was revisited during October, when it was discovered that the end of one solebar had splayed out, while that at the

diagonally opposite corner had toe-ed in! The headstocks are now in the process of being bolted up in their correct orientations, so that

the offending solebars can be returned to their correct positions.

Tom Simcock chain-drilling one of the headstock brackets on the radial drill in the C&W workshop at Horsted Keynes. David Chappell

July 2013

The brackets shown in the April 2013 progress report were cut back and replacement sections made from new material by Dave Deeks and

Martin Skrzetuszewski. All the welding, preparation and finishing was carried out by Andrew Breese. Here the brackets are shown in grey

undercoat in the paint shop. The holes for the rivets will be drilled out when the brackets are in situ on the under frame.

On a hot summer afternoon, Ray Tanner is tidying up the paintwork on the wheel sets and sorting out any areas which have been missed.

You can tell that it is hot, because Ray has removed his overcoat!

After protracted delays, a paid coded welder was brought in to repair the defects in the wagon underframe. The major cause for concern was

one of the legs in one of the axleguards/w-irons, which had fractured through a rivet hole. This had to be welded and reinforced. A new

rivet hole will need to be drilled and a longer rivet fitted.

A rivet hole in another axleguard was fractured through one side only, so this could be repaired by welding alone.

Several other cracks and areas of wastage were also repaired.

Photos by Martin Skrzetuszewski

May 2013

The old buffer holes in the two headstocks have had plugs welded in to fill them. New buffer holes and pilot holes for the rivets

(which secure the brackets on the end of the diagonal members) have been marked out and drilled by John Coleman, Tom Simcock and Martin

Skrzetuszewski. Here, John drills small pilot holes through the channel with an electric drill so that Tom can drill them through using

the radial drill (on the right).

The rivets holding the GWR brackets on the original diagonals have had their heads ground off and the brackets have been removed. The

Bristol Docks "alterations" can be seen. As the angle of the brackets is not 90 degrees, it may be more sensible to repair them rather

than renew them, despite their apparent condition. The crack in the original GW diagonal member was probably caused by the members being

forced over into new positions during repairs at Bristol. This has to be repaired by a coded welder; either one from Sheffield Park or a

contractor and has to be funded from project funds.

Photos by Martin Skrzetuszewski

February 2013

The two headstocks were removed during 2012 and are shown here on the floor of the paintshop in the afternoon of 3rd February. One has

being needle-gunned and primed by Paul Hailes and by the end of the evening, the second had been cleaned up and primed by him. At least

eight of the old holes in each of them will need to be filled with plugs welded in. The plugs have been recently cut from round steel bar.

More new holes will need to be drilled to fit the original-pattern buffers and re-positioned brackets for the diagonal underframe members

(moved when Bristol Docks fitted the new headstocks and Dowty buffers). In addition, two larger holes will need to be cut in each

headstock to accommodate the large nut on the back of each original GW buffer.

Photo by Martin Skrzetuszewski

November 2012

This photo taken in July 2012 by Martin Skrzetuszewski shows the two headstocks sitting on top of the under frame with an overhauled

buffer casting being used as a template to determine where the new fixing holes need to be. The two existing holes to the left of the

buffer will need to be plugged. Paul Hailes and Tom Simcock have progressively needle-gunned the underframe. Components which require

repair or replacement have been removed. Tom, Martin Skrzetuszewski and Ray Tanner have primed and brought the frame up to topcoat.

July 2012

The drawgear components have been dismantled, allowing the headstocks to be removed. The drawgear components have been cleaned up and

painted, ready for refitting. The headstocks are Bristol Docks replacements and are modified to fit the newer Dowty buffers that 87782 was

fitted with when purchased. They are also bolted on (instead of being riveted, so they are fairly easy to remove once the drawgear is out.

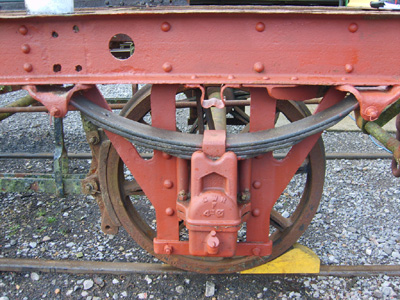

While the axles have been ultrasonically tested and have been passed for running, the axleboxes have been needle-gunned and cleaned up

and are shown being progressively painted up to topcoat inside the paint shop.

There are fractures in one leg each of two of the four axleguards ("W-irons" to some). These have been ground out by Eddie Carter to

facilitate welding, which will have to be undertaken by a (paid) coded welder, probably from the workshop at Sheffield Park.

Photos by Martin Skrzetuszewski

May 2012

The GWR buffers from Washford have all been dismantled, the components cleaned up, painted and re-assembled, the finished buffers being

put into store. This view shows the results of the work in progress. The short draw hook is from GW87782 but the red oxide coil springs

are for the buffers on SECR567. One GW buffer has been kept in component form to use as a template when the headstocks are removed, welded

up and re-drilled.

Paul Hailes has now needle-gunned the open-spoke wheel sets and the axle boxes show here. They have been primed and brought up to

topcoat by Robert Macmillan, Tom Simcock, Martin Skrzetuszewski and Ray Tanner.

The brake gear components, which were removed when the wheel sets were released, have also been cleaned up and painted.

Photos by Martin Skrzetuszewski

May 2011

Early in May the wagon underframe was moved by Mark Hailes to a position nearer the workshop, allowing access to air and electricity

supplies. The frame was subsequently lifted and the wheelsets were run out. This will allow the open-spoked wheels to be needle-gunned,

together with parts of the underframe which were previously obstructed by the wheels. The two cracked axle-guards can be examined and

repaired if possible. Once the 'continuous' drawgear has been dismantled the two headstocks can be removed for welding up and re-drilling

to take original-pattern buffers. Additionally a number of the existing securing brackets will need to be replaced, as a result of holes

being in the wrong place or having been badly gas cut oversize.

The similarity in design between this and the later SECR underframe for 567 is quite interesting. However, the more one looks at the

frame, the more one finds things that need repair or replacement - not unexpected on a vehicle that will be 100 years old this year, and

which has suffered several bodges during its career! It is therefore extremely unlikely that 87782 will be completed during 2011, but we

expect to make significant progress. (MS).

Photos by Martin Skrzetuszewski

September 2010

Work has been continuing on the buffer components. One remains

to be dismantled.

The two non-GWR body end tees from 87782 (having been extended - again courtesy of Eddie Carter - to modify them to the correct GWR

pattern) were trimmed to length on our mechanical hacksaw at HK and new holes were drilled using a broach bit mounted in our small radial

drill (shown below). In order to ensure that the dimensions were correct an original GWR tee was bolted to the back of the modified tee

and the holes drilled through.

Photo by Martin Skrzetuszewski

May 2010

We were lucky enough to be informed by Ollie Holmes of the Avon Valley Railway of the existence of a set of four GWR buffers, of the

correct pre-1915 pattern. These had been at Washford on the West Somerset Railway for some years. The Somerset and Dorset Railway Trust

very kindly sold them to us and C&W members Paul Hailes and Robert MacMillan kindly collected them from Washford in their van. Tom

Simcock, Robert and I started dismantling them, one by one.

Photo by Ollie Holmes

Paul Hailes has been needle-gunning the buffer components. A member of the management remarked that he had never understood what went on

at HK on Wednesday evenings until 10pm - well, this is one of the jobs that is best done outside normal working hours in order not to

disturb too many people.

Buffer casting after needle-gunning.

The other component parts of the buffers.

Robert MacMillan at work!

The results of his work: two primed buffer castings.

One needs a good sense of humour to spend an evening needle-gunning! Here is Paul Hailes grit-blasting some small components for

another project after working on items for 87782.

Tarpaulin rope cleats for 87782 removed from scrap sections of a tube wagon. These have been in stock since the early 1990s.

Photos by Martin Skrzetuszewski except where indicated

April 2010

Following a spell inside the carriage shed at the end of B-road, during which a fair amount of work was carried out, the underframe

was moved to a spot outside the paint shop. Whilst inside the underframe had been needle-gunned, primed and some sections undercoated.

Wasted sections of the top flange of the solebars were repaired by Eddie Carter and extraneous holes were filled in. Much of the brakegear

was removed for overhaul. Some of the brakegear brackets and safety loops will need to be replaced.

GW 87782 outside the paint shop.

Roger Barton's door pillars (with welding courtesy of Eddie Carter), almost complete, are now in primer.

The existing GWR door hinges, which were cut short at Bristol Docks, have been lengthened and now await drilling. The other set (not

shown) were non-GW and will have to be either modified or replaced with new.

Eddie Carter has machined up some new brake pins and spacers from steel bar purchased with funds from our generous donors. The drawings

for these were produced by Andy Prime.

Photos by Martin Skrzetuszewski

November 2009

At the end of October GW 87782 was moved outside the paint shop to allow easier access with air and electric tools. The first job was

to finish removing the non-original door stanchion fittings on the east side, nearest the camera in the picture below. Needle gunning of

the underframe then commenced with the nearest GWR OK 'F' axlebox and axleguard.

Upon cleaning up the axleguards, a stamping was observed 'GRC&WCo' which confirmed that this axleguard originated from the

Gloucester Railway Carriage and Wagon Company, the original builder of GW 87782. It is always nice to confirm which parts are original on

vehicles of this age, and if there was any doubt about the original number of GW 87782, it was confirmed by a further stamping of the

vehicle number on the left hand end of both solebars.

The final two pictures show the current progress of needle gunning and priming. Tom Simcock is shown cleaning up the solebar and I have

indicated in this picture the position where the vehicle number is stamped into the solebar.

Photos by Andy Prime

October 2009

15th October saw the arrival of GW 87782 from the up yard at

Horsted Keynes.

Photos by David Chappell

Over subsequent weekends all the old and rotten timber has been removed, several pieces being retained as patterns. The door pillars on

one side and the end tees at one end (all Port of Bristol Authority repairs) have been removed and put into stock for modification to

correct pattern or re-use on something more appropriate in the future.

September 2009

Since metrication and the diminishing of the British steel industry, many steel sections are no longer available. Two new door pillars

will be made from these four end stanchion tees (probably from a BR tube or pipe wagon) which have been on site for at least 15 years -

perhaps everything that looks like junk or scrap at Horsted Keynes is not so?

Roger Barton (a structural steelwork designer in a previous life!) is in charge of this job and is seen above preparing the replacement

door pillars.

Photos by Dave Clarke (left) and Andy Prime (right)

Go to the web page for this wagon

Return to BRPS Home Page,

to the Timetable or to Special

Events

Carriages & Wagons -

Intro -

Development -

Stock Lists: Carriages, Vans, Wagons & Multiple Units -

Carriage Fleet Review -

Join us

C&W Works News - SR Coach Group - Goods Division -

Operation Undercover -

Carriage Shop -

Technical Pages

Visitor Info. -

Museum -

Trust -

Catering -

Contacts -

What's New -

Projects -

Locos -

Carriages & Wagons -

Signals -

History -

Other -

Links -

Search -

FAQ

Why not become a BRPS Member? -

Get more involved as a Volunteer

Your ideal Film/TV location?

Page last updated by Nick Beck, 23 October 2014 and Richard Salmon, 29 March 2022

Page last updated by Nick Beck, 23 October 2014 and Richard Salmon, 29 March 2022

Text © Martin Skrzetuszewski

Photos © as credited

© Copyright BRPS. Privacy Policy

|