Carriage & Wagon Dept -

Stock Lists: Carriages, Vans, Wagons & Multiple Units -

C&W News

SR Coach Group - Goods Division -

Operation Undercover -

Technical -

Join us

Carriage & Wagon Works News

B741381 BR 12 Ton "Pipefit"

Dropside Open Wagon

One of the more recent arrivals on the railway is the diagram 1/462 "pipefit" wagon. When it was delivered, it

was wearing faded Satlink livery, and permission was given for the vehicle to have a repaint and some of the

damaged planks replaced. The wagon has been restored to the condition that it would have been

seen in sometime after its first trip back to the works for attention. With the underframe and other metalwork

being fifty years old, it would be virtually impossible to restore to ex-works condition, especially as there are

obvious external signs that, in a previous replanking, oxy-acetalene was used rather enthusiastically in removing

the old bolts! A small team consisting of Martin Skrzetuszweski, Nick Beck, Andy Prime and David Chappell have undertaking

the majority of the work, with much appreciated assistance from other members of the department, such as Tom Simcock,

'Robert Robert' Macmillan, Paul Hailes and Ray Tanner.

12 April 2007

These two photos from Andy Prime, taken on 12th April show the completed Pipefit being shunted into one of the two goods trains ready for its relaunch into service on the Goods Train weekend.

These two photos from Andy Prime, taken on 12th April show the completed Pipefit being shunted into one of the two goods trains ready for its relaunch into service on the Goods Train weekend.

March 2007

Over the next two months the planking (much replacement, but some retained) was prepared, painted and fitted. This was largely done outside the shed, since the space in the shed was taken by the Metropolitan brake.

Dave Clarke's photo shows that, by the end of March the finishing touches were being applied - here we see Start Fielder's signwrighting. Mechanical maintenance was completed at the start of April, and it should be running for the Goods Train weekend.

January 2007

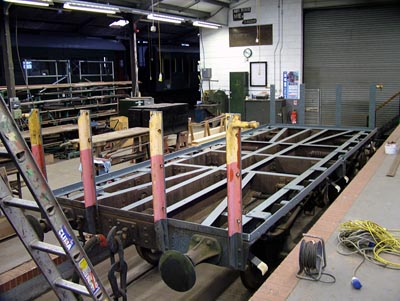

By 6 January, the cleaning has been completed, and the paint fairy has applied primer to the outer angles of the floor.

All the end stanchions have been painted up to undercoat level, and some of the new planks in the background have been

machined down to the correct thickness, a job which is an awful lot more hard work than it sounds. The hinges are now

all cleaned up and painted, and the salvaged timbers have been stripped and primed with aluminium primer.

A week later, the newly primed parts have been undercoated, and finally the chance to put some top coat on has arrived.

A good number of hours later, everything has had a coat of gloss. While the edge of the wagon may appear to have

reverted back to primer, it is in fact BR wagon brown.....

December 2006

The wagon has now been given a brief stay in the workshop, and it is hoped that as much of the retimbering work can be

carried out in the warmth rather than outside in the freezing December and January weather!

These two views provided by David Chappell from 6 December show the floor of the wagon before removal. At some point the floor of the vehicle

was covered with a number of ply sheets, presumably due to the planks being damaged or partially rotten. This 'fix' has in turn

led to water being caught between the two layers, causing the planks to rot extensively, as the plank in the foreground shows!

As can be seen, despite being indoors and the weather having been fairly dry recently the floor of the wagon is extremely

damp, and none of the timber will be reused. In the background, it appears that one of the most critical tasks involved in

working on a voluntary team is taking place - Martin is replenishing the tea supply!

This picture shows

the wagon in the morning, on 16 December 2006, just before work on cleaning the underframe began. Initially, it

was planned to replace the floor at a later stage, but given the worse that anticipated rot, it has now been agreed

that the floor will be replaced too. The reusable planks are currently stored away form the main workshop,

where Martin Skrzetuszewski, David Chappell and Nick Beck have spent many hours sanding off the rather faded

Satlink colours in preparation for a more appropriate livery.

After a considerable amount of cleaning using an angle-grinder with a wire brush attachment, the underframe now has

most of the top surfaces of the members painted. The outer angles have not been subject to this treatement as

they have more extensive build-up on them and require needlegunning to achieve the best result. The remaining

hinges have also been removed, and thanks go to Tom Simcock for gritblasting some of them while the other work was

going on. The eagle-eyed may notice that the time on the clock is almost precisely nine hours to the minute

after the previous picture was taken - eight and a half of those hours were needed before the primer was opened!

By Christmas Eve, all the primed surfaces have been painted with undercoat, with other painting and cleaning tasks

being carried out elsewhere on the underframe.

A few days later, on 27 December, the outside edges of the outer angles have been cleaned and primed, but the inside

edges still require attention to remove the extensive corrosion on them.

As luck would have it, the next day saw the regular shunt take place, and the Pullman set brought up for annual attention.

This meant that the wagon would be moved outside and this would give the opportunity to employ a descaler on the corroded portion

of the angles. Some of this can be seen in these pictures taken outside the workshop.

Devoid of any woodwork, the wagon underframe looks rather spindly to say the least, however, looks can be deceiving!

This view along the angle that forms the edge of the floor shows the extent of the corrosion that needs to be removed

before it can be repainted, this was caused by the rotting floor.

Unfortunately, neither of the descalers in the workshop have proved to be suitable for the task as they currently lack

any real power. Hopefully they can be repaired or replaced in due course, but in the meantime the night shift has arrived

in the form of David Chappell. Chipping off the rust by hand is a very long and intensive progress to say the least! To the

right of the picture can be seen the new timber for the doors and ends of the wagon, which requires machining to size.

October 2006

After struggling to remove individual planks from the doors due to the internal strapping, it was decided that it

would be far easier and quicker to remove all the planks from the wagon rather than those most obviously in need of

replacement. This would also allow a more thorough examination of all the planks for damage and rot. At

present it is unsure quite how many of the existing planks can be reused, but it appears to be between approximately

a quarter to a half. The stacked planks (12) are shortlisted for reuse, the others are to be examined for suitability.

All the metalwork needs cleaning up and repainting, which is a long and labour intensive process that usually

involves lots of noise and dust. Here Martin Skrzetuszewski is working on one of the hinges. Various other

metal parts have been removed and thanks are due to 'Robert Robert' MacMillan for gritblasting them.

September 2006

The south end of the pipefit wagon appears to be relatively sound, however, several of the planks have split, and

there are signs of rot in several others. In addition, the vacuum hose is badly perished and will need either

extensive repair or replacement.

The north end of the wagon will need a little more work. Several of the top planks have rotted underneath

their capping strips, and the north-east door has a couple of filling strips which have been used to make replacement

planks the correct height.

After several hours, a number of the condemned planks have been removed. There are still many more to go!

As can be seen, a previous quick fix done by the previous owners has seen the floor covered with plywood, which

has now started to rot. It is believed that this was put down in preference to replanking the floor, hopefully

the planks underneath will be more sound than this implies.

Go to the web page for this wagon

Return to BRPS Home Page,

to the Timetable or to Special

Events

Carriages & Wagons -

Intro -

Development -

Stock Lists: Carriages, Vans, Wagons & Multiple Units -

Carriage Fleet Review -

Join us

C&W Works News - SR Coach Group - Goods Division -

Operation Undercover -

Carriage Shop -

Technical Pages

Visitor Info. -

Museum -

Trust -

Catering -

Contacts -

What's New -

Projects -

Locos -

Carriages & Wagons -

Signals -

History -

Other -

Links -

Search -

FAQ

Why not become a BRPS Member? -

Get more involved as a Volunteer

Your ideal Film/TV location?

Page last updated by Nick Beck, 14 January 2007, Richard Salmon 20 July 2007

Page last updated by Nick Beck, 14 January 2007, Richard Salmon 20 July 2007

Photos © Nick Beck unless otherwise credited

© Copyright BRPS. Privacy Policy

|