Current Infrastucture News Current Infrastucture News

Archive of Infrastucture News: 2013-14 - 2015-16 - 2017 - 2018 - 2019 - 2020 - 2021-22 - 2023

Archive Reports: Northern Extension Project -

Permanent Way and Lineside News (2007-2011) - P-Way News (2002-4)

Track relaying on Freshfield Bank 2011

Text and photographs: Michael Hopps

Clicking on the images will take you to a larger version of each photo showing more detail.

|

Bluebell operates a service nearly all year round, but between Christmas and Easter each year a major infrastructure job is

tackled in the slack period before the start of the new season when the line can afford to be closed for a pre-arranged period. Last year the

Infrastructure and PW gangs re-laid the track in the tunnel during a three-week closure, and valuable experience was gained which has since been

put to good use both at East Grinstead and in this year’s major job: the upgrading and re-laying of a 260-yard section of Freshfield Bank. |

| |

|

|

|

|

|

| |

|

|

|

A Santa Special train pictured at the site of the re-laid section on 5th December 2010. |

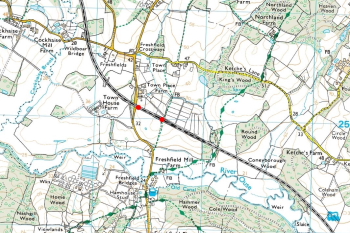

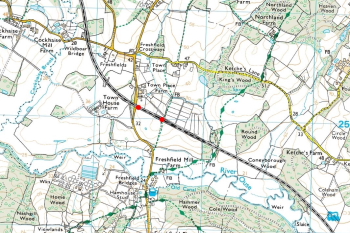

This is the section that was re-laid – the top end of Freshfield Bank just before

Sloop Bridge. |

The view from the same position as the 5th December photo, when the job was nearly finished. |

| |

|

|

|

|

|

| |

|

|

|

Installing the drain inspection chambers underneath Town Place Bridge. |

Just before the possession – the last public train from Horsted Keynes to Sheffield Park. |

Covering the drainage pipes with shingle over the geotextile membrane. |

| |

|

|

|

The section in the cutting at the northernmost end of the bank between Town Place Bridge and Sloop Bridge

has long had various speed restrictions in place, as poor drainage combined with the passing of trains has caused clay to work up into the ballast

from underneath. When the line was originally laid it obviously seemed sufficient to level the track bed, put down a layer of ballast and

install rudimentary drains in particularly wet areas. However it is now accepted and preferred practice in permanent way to use more modern

materials to increase stability, suppress weed growth and improve drainage – which also reduces operating costs in the long term. Bluebell

is now making regular use of ‘Terram’™ polyethylene/polypropylene geotextile mat along with black polythene membranes to aid drainage and to

prevent the subsoil from working up through the ballast. This combination has been used extensively in the cutting leading up to the tip at Imberhorne, and

was also employed in repairs at Black Hut last year. |

| |

|

|

|

|

|

| |

|

|

|

Grading the down side ready to slew the track across for working access. |

Track now slewed across, and the digger removing the old ballast. Geotextile

mat and polyethylene membrane laid before new ballast is spread. |

Scraping the old track bed back to the clay and chalk base. |

| |

|

|

|

|

|

| |

|

|

|

Loading old ballast ready to be taken away. |

It bends almost as easily as the model variety! |

Waiting for the green flag. |

| |

|

|

|

The work was carried out mostly by the mid-week Infrastructure/NEP Gang led by Matt Crawford, the

Infrastructure Manager, but members of the Sunday and Thursday PW gangs also took part on various days. We were greatly assisted by contractors

L&W who are also involved in work at East Grinstead and who provided the road-railer, bulldozer and other items of heavy plant – without which the

job would have taken a lot longer and would have needed many more volunteers. |

|

|

|

|

Lots of fishplate holes to drill. |

Even lengths of rail are barcoded these days! |

Drilling holes before the ‘new’ sleepers are delivered. The road-railer is now unable to travel further and is used for

bringing up supplies and personnel from Sheffield Park. |

|

|

|

|

592 has just delivered ballast to the site. |

This is how you get a bulldozer onto a train – in case you were wondering! |

Grading the new track bed with the laser dozer. |

| |

|

|

|

Starting at the bottom as in so many construction jobs, drainage was the first thing to be sorted out. Existing drains and

gulleys on the down side had been cleared out before Christmas, but an extra drain was installed on the up side as well; this will be

extended southwards as other sections of the bank are replaced. The drains are a modified version of the traditional ‘French drain’ which is

fast becoming a standard on the Bluebell. Perforated plastic drain pipe is laid in a gulley surrounded by shingle and ballast, and wrapped with a

layer of ‘Terram’ to stop silt getting into the pipe – which would otherwise fill it up in a matter of months. This arrangement has the

advantage of being able to cope with the heavy flows in particularly wet weather; being perforated the pipe allows the ground beneath the track to

retain some moisture and allows a more even distribution of the flow from wetter to drier parts. This is essential in heavy clay areas to prevent

movement. At the joint between each length of pipe an intercept is created using a larger version of the same pipe, which is capped off neatly

just above ground level. This is a very quick and easy way of providing access; it is much cheaper than a traditional brick-built chamber, and has the

added advantage of easy removal when the drains need to be serviced. Work started on the up side drains in the week preceding the closure, but full

possession of the line beyond Sheffield Park outer home signal was taken on Monday 17th January and the work gang moved up the line that morning to

start work on the down side drains and to move materials to the site. |

| |

|

|

|

|

|

| |

|

|

|

Old level – New level! |

Rock and roll. |

Top of the bank. |

| |

|

|

|

|

|

| |

|

|

|

Much easier than lifting by hand. What would Brunel have given for one of these! |

Road-railer now back in use lifting new sections of rail. |

Adjusting the pitch and alignment of sleepers. |

| |

|

|

|

When the line was originally built provision had been made for a second running

line south of Horsted Keynes, but it was never laid and the line has always been single tracked. This extra space on the down side meant that what was

effectively a temporary track could be used to service the site while the old track bed was completely renewed. Without this facility the job would

probably have taken much longer. The day after the down side drains were installed the ground beside the track bed was levelled with the digger

and the running line was disconnected directly beneath Town Place Bridge. Then the existing track northwards was slewed across by the

digger almost all the way to Sloop Bridge, at a point where the new track was to meet the existing formation. With the road-railer now south of the

work site and only being used to transport supplies and personnel from Sheffield Park, another train was needed to bring in rails from Horsted

Keynes and sleepers and ballast from West Hoathly. Diesel shunter no 13236 had been moved to Horsted Keynes in advance of the work starting, but as

insurance SECR ‘C’ class no 592 had also been stabled at Horsted Keynes – which as it turned out was a very wise precaution. |

| |

|

|

|

|

|

| |

|

|

|

Sleepers not quite in line yet. |

A bit of an adjustment... |

Levering track into place before clipping. |

| |

|

|

|

|

|

| |

|

|

|

Doing up the nuts! |

A nice neat job. |

New meets old. The best and safest practice is to have the ends of the new rail

supported on wooden sleepers rather than having a concrete/wood transition around the joint. |

| |

|

|

|

With the track slewed across, work could start on removing the existing ballast so that the plastic

membrane and geotextile mat could be installed. This was spread wide enough for the edge to be tucked into the drain gulley on the up

side. The old ballast was loaded into wagons pulled by 13236 and was removed from site – some of better quality to be re-used for

drainage, but most just kept for fill on non-trackwork jobs. New ballast was then laid on top of the geotextile/membrane sandwich and roughly

levelled to sleeper base depth by the digger. Having the track slewed across meant that the whole of the new formation could be cleaned and

renewed in one go, rather than doing it panel by panel. The new 60ft lengths of flat bottomed 113lb/yd (a) rails which had been delivered to

the Salt Yard at Horsted Keynes were transferred down to the site and laid between the rails of the slewed track. In all there were 26 rails to make

up 13 panels. They were all drilled ready for laying, so that time was gained while other work was going on with the track bed – with the exception of the

pair to be used at the top end, which needed to be cut to fit to the existing formation by Sloop Bridge. |

| |

|

|

|

|

|

| |

|

|

|

Checking

levels and alignment against pegs which mark the original formation. |

Special

fishplates are needed to join bullhead and flat-bottomed rail sections. |

Fixing ‘Pandrol’

clips. (Photo: Stuart Moon) |

| |

|

|

|

|

|

| |

|

|

|

Looking north from the start of the new section. |

Firewood brought up from Sheffield Park. |

Looking back to Sheffield Park, with the original track on the down side before

lifting. |

| |

|

|

|

Very early on in operations the diesel 13236 failed and so 592, which had been waiting patiently in the

wings, found itself needed in a hurry and quickly became the star attraction – not only for being useful in pulling the site trains but

providing a never-to-be-forgotten experience for any railway photographer (and everybody else) who happened to be around! The 24th January

was a memorable day as 592 arrived from Horsted Keynes with a load of ballast but also carrying the laser-guided bulldozer on a well

wagon. The ‘dozer’ started work at the south end of the site and in a relatively short time had graded the 200 or so yards needed, ready for

rolling prior to track-laying. The road-railer brought up the vibrator/roller from Sheffield Park to compact the new track bed and then the

give-or-take 364 (new) concrete sleepers were delivered from West Hoathly and set out to a 28-per-panel spacing. Work on laying new panels

proceeded very quickly and, after the first panel was connected to the existing formation at Crown Place Bridge, the road-railer could again be

used to lift rail and sleepers – and the occasional bag of coal and firewood. 592, which was now working full time on our celebrated ‘all

steam’ railway, was of course unable to get back to Sheffield Park for its usual wash and brush up! |

| |

|

|

|

|

|

| |

|

|

|

A little local adjustment before the clips are put in. |

Sleepers down and ready for the next pair of rails. |

Putting the mat down before the last section is ballasted. |

| |

|

|

|

|

|

| |

|

|

|

Cutting the old track section to fit in the last panel. |

Grading the last small section where the laser dozer couldn’t go. |

Ready for the last panel to be installed. |

| |

|

|

|

With track-laying almost completed by the end of the second week, Saturday 29th January saw the last panel

connected to the running line ready for final ballasting and tamping. With the line now connected again, the old (temporary) track was broken up

and the rails removed to the Salt Yard to await disposal or re-use. The old wooden sleepers were sorted – into re-usable, still fairly useful, and

firewood – and stacked ready to be taken back to the Salt Yard by the Sunday PW gang. The old chairs have been salvaged as well, ready to be

graded and re-used if possible. It was hoped to use panels of the old formation as temporary track at the Imberhorne Tip, but a decision was

made to make up short panels back at the yard using only the best second-hand materials. At the time of writing the Thursday PW gang has

already made up three half panels, ready to be transported to East Grinstead to extend the track at the tip as the digging gets under way

towards the end of February. |

| |

|

|

|

|

|

| |

|

|

|

After three weeks Horsted Keynes is connected to Sheffield Park again. |

A ballast train arrives from West Hoathly. |

Getting ready for the first ballast drop. |

| |

|

|

|

|

|

| |

|

|

|

Ballasting in progress. |

It doesn’t get much better than this for a volunteer with a camera! |

The top of Freshfield Bank is clearly visible as 592 attacks the gradient. |

| |

|

|

|

The ballast train arrived on Monday 31st and, apart from being useful, 592 made a splendid sight hauling a

traditional train on this very bright but extremely cold day. Several runs were made with three loads of ballast, which was dropped between and

around the rails ready for the tamper to do its work. The road-railer was also used after the ballast drop to spread the ballast evenly with a

plough, which saves an awful lot of shovelling by hand! |

| |

|

|

|

|

|

|

|

|

|

|

Drainage access point with cover in place after trimming to ballast level. |

This special tool is used to remove conductor rail insulator clamps. |

Coal was brought up from Sheffield Park on the road-railer in a builder’s bag, and then

transferred to 592 with the digger. |

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

Collecting all the ‘old’ sleepers which might be re-usable elsewhere on lighter duties. |

Pretty good – even before tamping. |

The tamper making its first pass from the south, going uphill. |

| |

|

|

|

Finally, on a cold and very damp 1st February, the tamper travelled up from Sheffield Park and made a number of

runs up and down the new section. There was still some clearing of undergrowth to do on the down side, but the rest of that week was spent

returning plant, tools and supplies back to Sheffield Park. After a final inspection, possession was handed back to the operating department

and the first public trains were allowed over the new section on Saturday 5th February. |

| |

|

|

|

|

|

| |

|

|

|

Still a bit of measuring going on in the background before the final tamping. |

The ballast is much deeper than before, to allow tamping without disturbing the membrane beneath. |

Second pass of the tamper, nearing the top of the grade. |

| |

|

|

|

|

|

| |

|

|

|

Phoenix platelayers’ hut provided a base for operations. |

Happy in their work – the end of another successful day for the volunteer track workers. |

Home from home and with kettle at the ready for another January day! |

| |

|

|

|

Undoubtedly having 592 on site and working for many days was a particular highlight and will remain in the memories of the

enthusiastic volunteers for a long time to come. However other little historic touches, harking back to earlier days, were also enjoyed by the

workers. Phoenix platelayers’ hut near Sloop Bridge became the mess room for the project, and when arriving for tea, biscuits and scones we were

greeted by a real fire with coal pinched from 592 and even a clock on the wall (but sadly not a Joyce, Seth Thomas or Maple) in case anyone

forgot what century they were in!

Altogether it was a very worthwhile project, and there was a great sense of achievement for all concerned. Do workers with Network Rail get

this much entertainment value? I doubt it!

If you are not already a working member we would be pleased if you could join us and share in the fun. |

| |

|

|

|

|

|

| |

|

|

|

SECR ‘P’ class no 178 attacking the ‘Bank’ with the noon service to Kingscote on 5th February 2011. |

Well, we won’t need this any more! |

What a nice finish. LBSCR ‘E4’ class no 473 with the first down train of resumed public service on 5th February 2011. |

| |

|

|

All photographs and text are © copyright Michael

Hopps.

Return to BRPS Home Page,

to the Timetable or to Special

Events

Current Infrastucture News Current Infrastucture News

Archive of Infrastucture News: 2013-14 - 2015-16 - 2017 - 2018 - 2019 - 2020 - 2021-22 - 2023

Archive Reports: Northern Extension Project -

Permanent Way and Lineside News (2007-2011) - P-Way News (2002-4)

Visitor Info. -

Museum -

Trust -

Catering -

Contacts -

What's New -

Projects -

Locos -

Carriages & Wagons -

Signals -

History -

Other -

Links -

Search -

FAQ

Why not become a BRPS Member? -

Get more involved as a Volunteer

Your ideal Film/TV location?

This page last updated 27 March 2011 by Michael Hopps, 31 March 2011 by Richard

Salmon, and 4 April 2011 by Jon Elphick

This page last updated 27 March 2011 by Michael Hopps, 31 March 2011 by Richard

Salmon, and 4 April 2011 by Jon Elphick

© Copyright BRPS. Privacy Policy

|